Pure Performance: Saving Time with Ultra Fast Preparative LC

How Syngenta is using UFPLC to extract and purify gram-scale by-products for regulatory testing

Syngenta

-

INDUSTRY

Environment

-

KEYWORD

UFPLC, prep LC

-

INTRODUCTION SERVICE&PRODUCTS

Preparative LC, Ultra Fast Preparative Liquid Chromatography

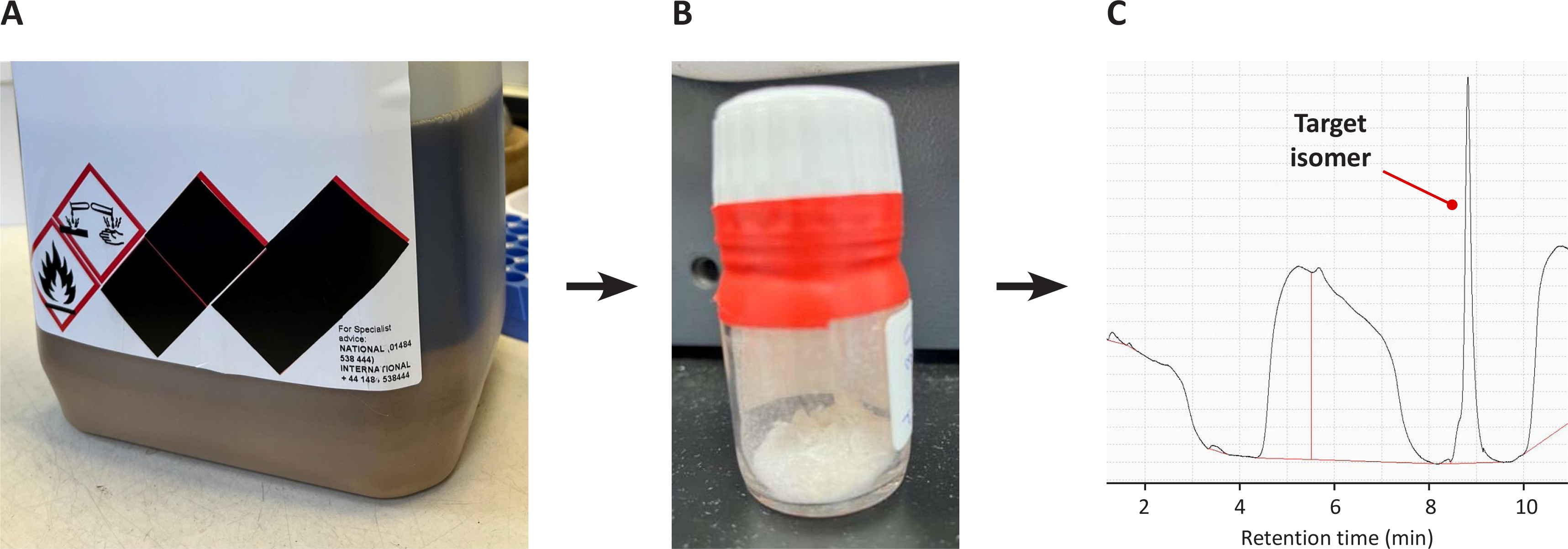

In this article, we talk to Syngenta about how they’re using Shimadzu’s Ultra-Fast Preparative LC (UFPLC) systems to speed up the extraction and purification of gram-quantities of by-products that are present in technical-grade active-ingredient material at levels below 1%, so providing the material needed for regulatory tests and toxicity studies.

As a heavily-regulated industry, crop protection products must meet numerous criteria before they can be registered for use, which includes rigorous tests to assess their safety for workers, the environment, crops and consumers. Isolating by-products in usable quantities is where separation scientists such as Louise Bacon come in. Her team helps their colleagues around the world with the toughest of separation challenges, with the help of preparative-scale liquid chromatography.

Louise Bacon - Team Lead for the Preparative and Isolation Chemistry Team, Jealott’s Hill International Research Centre, Bracknell, UK

“We see the greatest value of UFPLC in cases where we have large volumes of impure material requiring hundreds or even thousands of injections. Using HPLC would generate multi-litre quantities of fractions, which would slow us down because of the backlog of samples awaiting evaporation, especially when we’re being asked to collect multiple products. But with the Shimadzu system we can automate the collection of up to five fractions with no manual intervention”.

Louise Bacon (centre), with her colleagues Cyprien Bone (left) and Lorraine Ezra (right) in the Preparative and Isolation Chemistry Team at Syngenta.

“Reducing our solvent usage is a major benefit of using UFPLC, and one we’re going to be looking at more”, says Louise. “On a prep HPLC method, you might be running thousands of injections on a 20 minute method at 50 mL per minute – which generates a vast amount of solvent to evaporate and ultimately dispose of. But with UFPLC, we reduce that need for solvents and the associated energy costs in evaporating them, as well as being able to use more environmentally benign solvents”.

In conclusion, says Louise, with the help of the Shimadzu UFPLC they’ve been able to achieve what was previously very difficult – the extraction of sub-percent levels of by-products from very complex mixtures, all while keeping solvent usage down, minimising degradation of the target compounds, and reducing manual processing to the bare minimum. As she concludes, “It’s been brilliant, absolutely brilliant, and saved us so much time!”.

Louise Bacon

Louise Bacon - Team Lead for the Preparative and Isolation Chemistry Team, Jealott’s Hill International Research Centre, Bracknell, UK

*Affiliates and titles of the interviewee are current as of the time of reporting.

Syngenta

URL

https://www.syngenta.com/en