UCL - Custom GC Instruments Drive Major Breakthroughs in Chemical Engineering

Custom GC helps UCL researchers explore new frontiers in chemical engineering

University College London

-

INDUSTRY

Chemicals, Clean Energy, Carbon neutrality

-

KEYWORD

chemical engineering, custom gas systems

-

INTRODUCTION SERVICE&PRODUCTS

Custom GC helps UCL researchers explore new frontiers in chemical engineering

The need to improve the environmental credentials of the processes used to make commodity chemicals and fuels, and the desire to make use of waste industrial gases such as CO2, is driving a whole new field of research into novel chemical processes. Foremost amongst the institutions following this path is the Centre for Nature-Inspired Engineering (CNIE) at University College London (UCL).

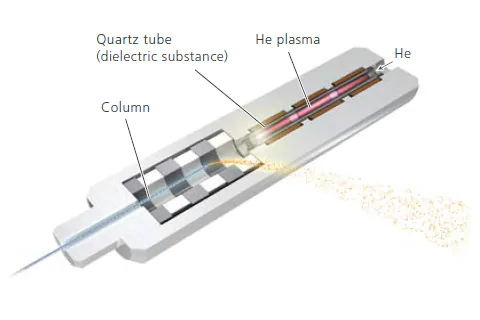

Since 2018, Dr Han Wu has been Research Lab Manager not only for CNIE, but also for the entire department, overseeing the acquisition and maintenance of a wide range of analytical instrumentation, including more than ten gas chromatography (GC) and high-performance liquid chromatography (HPLC) instruments that are crucial to many research projects. This gives her a unique perspective on how the capabilities of the instrumentation are linked to the success of the research.

Dr Wu commented: “When I first started as a member of the technical staff at UCL in 2013, there was a common viewpoint in academia that there was no major difference between GC suppliers. But once I started to get into discussions with the vendors, I came to realize that there’s a huge difference in their way of supporting their customers – and for me that is a big highlight of working with Shimadzu”.

Dr Nidhi Kapil has been using the custom on-line GC–FID/TCD to study the catalyst-mediated oxidation of propylene to the commodity chemical propylene oxide. The aim is to develop more sustainable routes than the current chlorohydrin and hydroperoxide processes, which generate a lot of waste chemicals.

“I’ve worked on the project since it started – not only refining the reaction and optimizing the catalyst, but designing the reactor too. I started out using nanoparticle catalysts, and then proceeded to the meso and macro scales by taking advantage of zeolite supports”.

Dr Kapil commented: “To start with, we ran the system for about 4 hours, but ultimately we were able to leave it going for up to 30 days, taking measurements every 40 minutes or so. Its reproducibility meant that we could monitor the performance of the catalyst over longer periods, and the networked GC meant that I could monitor the system – even when I was away for four days at a conference in the USA!”.

Further Reading

For more information about Dr Kapil’s work on catalysts for propylene oxidation, please see:

- N. Kapil, F. Cardinale, T. Weissenberger, P. Trogadas, T.A. Nijhuis, M.M. Nigra and M.-O. Coppens, Gold nanoparticles with tailored size through ligand modification for catalytic applications, Chemical Communications, 2021, 57: 10775–10778, http://doi.org/10.1039/d1cc04165g.

- T. Weissenberger, N. Kapil, P. Trogadas and M.-O. Coppens, One-pot synthesis of hierarchical, micro-macroporous zeolites with encapsulated metal particles as sinter-resistant, bifunctional catalysts, ChemCatChem, 2022, e202200268, http://doi.org/10.1002/cctc.202200268.

- N. Kapil, T. Weissenberger, F. Cardinale, P. Trogadas, T.A. Nijhuis, M.M. Nigra and M.-O. Coppens, Precisely engineered supported gold clusters as a stable catalyst for propylene epoxidation, Angewandte Chemie, International Edition, 2021, 60: 18185–18193, http://doi.org/10.1002/anie.202104952.

If you’d like to read more about the work at UCL using Shimadzu’s GC systems, then please see:

- J. Xie, R. Jin, A. Li, Y. Bi, Q. Ruan, Y. Deng, Y. Zhang, S. Yao,, G. Sankar, D. Ma and J. Tang, Highly selective oxidation of methane to methanol at ambient conditions by titanium dioxide-supported iron species, Nature Catalysis, 2018, 1: 889–896, http://doi.org/10.1038/s41929-018-0170-x

- R. Xu, L. Kang, J. Knossalla, J. Mielby, Q. Wang, B. Wang, J. Feng, G. He, Y. Qin, J. Xie, A.-C. Swertz, Q. He, S. Kegnæs, D.J.L. Brett, F. Schüth and F.R. Wang, Nanoporous carbon: Liquid-free synthesis and geometry-dependent catalytic performance, ACS Nano, 2019, 13: 2463–2472, http://10.1021/acsnano.8b09399.

- Q. Wang, X. Guan, L. Kang, B. Wang, L. Sheng and F.R. Wang, Polyphenylene as an active support for Ru-catalyzed hydrogenolysis of 5‑hydroxymethylfurfural, ACS Applied Materials & Interfaces, 2020, 12: 53712−53718, https://doi.org/10.1021/acsami.0c11888.