The Nexera series is a family of HPLC systems that marries AI and IoT enhancements to set new industry standards.

Preventive Measures

HPLC Troubleshooting Course

1 - Basics of Systematic Troubleshooting

2 - Preventive Maintenance Measures

3 - Baseline Disturbances

4 - Pressure Fluctuations

5 - Changes in Peak Shape - Part 1

6 - Changes in Peak Shape - Part 2

7 - Ghost Peaks

8 - Peak Area Fluctuations

9 - Retention Time Fluctuations - Part 1

10 - Retention Time Fluctuations - Part 2

11 - Column Lifespan - Part 1

12 - Column Lifespan - Part 2

13 - Detector Issues

14 - Flow Line Leakage

15 - Course Summary

Preventive Measures

The second part of the Troubleshooting course focuses on preventive measures that can extend the lifespan of your equipment. When these practises are consistently applied, you will experience fewer issues with your equipment and columns, therefore getting better and more reproducible separations, with fewer errors. We will cover both optional and essential actions that can inevitably lead to errors if neglected.

1. Preventing Blockages

If small microparticles are introduced into the HPLC flow path, they can lead to clogging of the capillaries, valves, and separation columns – issues that may require costly parts or column replacements. Therefore, as part of your sample preparation, samples should be filtered through a a 0.22 µm syringe filter tip to remove particulates. Standards also need to be filtered in the same way. Filter tips can be be purchased in different materials; be sure to choose one that doesn’t absorb your analytes which can lead to falsely low results.

When working with 100% water mobile phase, it’s easy for microorganisms to grow which may lead to blockages. It’s therefore important to use water from a lab water filter system (e.g. Milli-Q water), to buy sterilised HPLC-grade water or adding an acidic or alkali modifier to the mobile phase, making it harder for microorganisms to grow. Regularly renewing the aqueous mobile phase is also recommended to mitigate this risk.

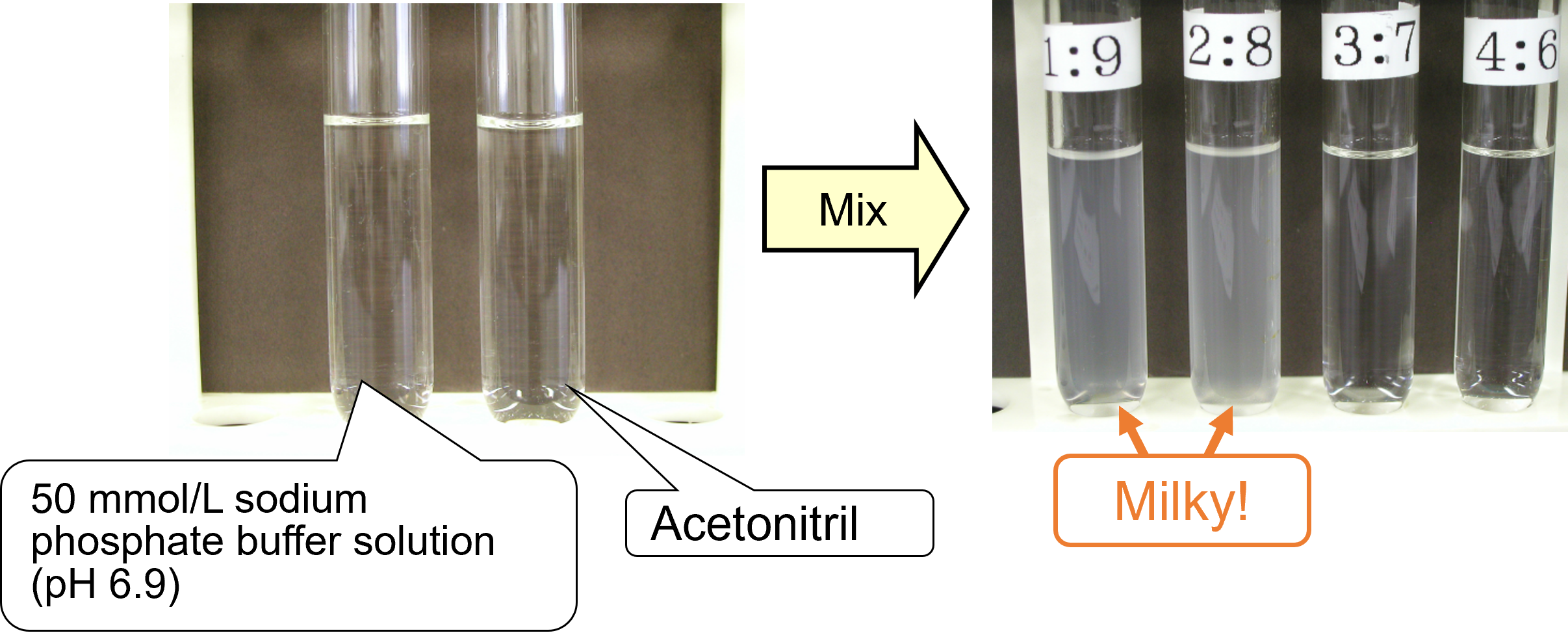

When using buffers, it is important to consider their compatibility with organic solvents. When using high concentrations of organic modifier or ionic strength of buffer, the buffer may precipitate, leading to blockages in the system. Preliminary tests on compatibility are therefore recommended.

It is also important to consider solvent miscibility when switching mobile phases on the HPLC. The HPLC should be flushed through with a miscible intermediate solvent if it is likely that the new solvent won’t be miscible with the original solvent. For example, if switching from an acidic to a basic modifier, the system should be thoroughly flushed with a neutral mobile phase.

2. Flushing

Contamination of the flow line or the column can have a significant impact on chromatography. If the column is not clean, the back pressure can increase substantially, or the selectivity of the phase can change permanently. When using samples that have a high affinity to the column being used, incorporating a cleaning step with a strong solvent into every method is essential. If the column becomes heavily contaminated, directing the flow to waste will prevent contaminants from reaching the detector. Additionally, the flow path can be flushed with appropriate solvents without a column in place, by using a backpressure capillary.

3. Degassing

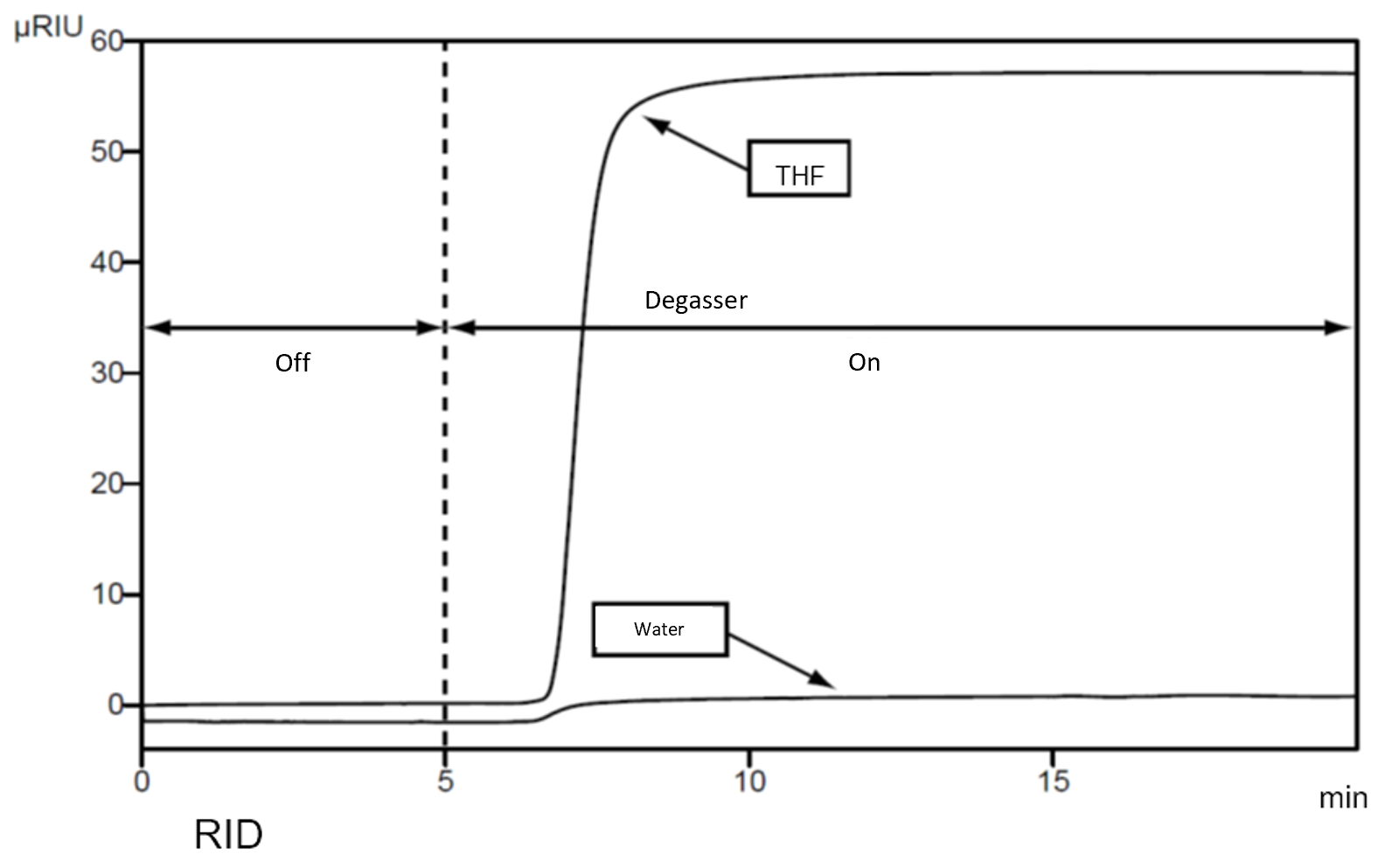

Dissolved air in the mobile phase has a significant impact on baseline stability and the signal-to-noise ratio. The image on the right shows the effect of dissolved air in water and THF on the baseline of a refractive index detector (RID) when the degassing unit was switched ON after the baseline had stabilised with the degassing unit OFF. Decreasing the dissolved air when the degasser was switched on increases the refractive index; and the change in refractive index is greater for THF than for water. In general, the lower the polarity of a solvent, the greater the effect a change in dissolved air has on the refractive index.

Additionally, excess dissolved air can lead to the formation of air bubbles, much like releasing pressure from a water bottle. Therefore, using an online degasser is highly recommended for optimal performance. Trapped air bubbles in the pistons can cause considerable ripple in the pressure trace which can cause poor reproducibility in chromatographic results. Should this happen, the system should be purged to remove the trapped bubbles, or use a solvent such as 2-propanol to help remove stubborn air bubbles.

4. Temperature Control

Temperature is a major factor in HPLC as it significantly affects both chromatography and detector sensitivity. Increases in column temperature decreases the viscosity of the eluents (mobile phase), leading to lower pressure, and altered retention times. The same applies to the detectors. Depending on the temperature, the sensitivity and baseline can change, which is why so many detectors have their own temperature control. Fluctuations in room temperature can also affect the quality of the chromatography. Therefore, where possible, you should keep your system temperature controlled. This can be achieved through a column oven, heated cells, and the right choice of installation location. Avoid placing the system in areas with a draft, in direct sunlight or near external heat or cooling sources.

5. Detector Settings

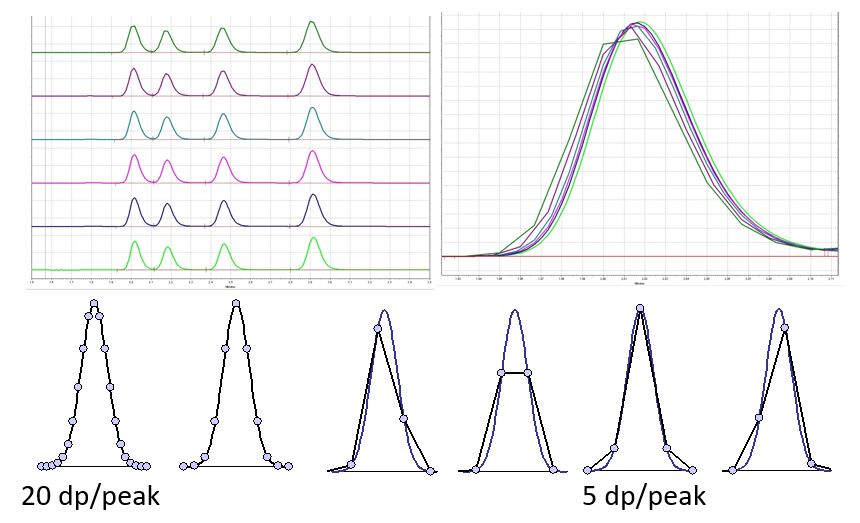

Accurate setting of the data acquisition rate of the detector is often overlooked. An improper setting can lead to significant variation in peak area. The data acquisition rate should be adjusted to the narrowest peak width. If it is too low, the peak will not be reproducibly represented, as the peak is poorly described. A too high setting will result in increased noise and a much larger datafile. At least 20 data points across the peak width are necessary to describe a Gaussian-shaped peak. The data points are set by changing the Hz detector settings, whereby 1 Hz is one cycle per second. Therefore, the shorter the chromatographic run, the higher the data rate / Hz needs to be.

Following these five preventive measures can proactively avoid many common errors in HPLC. Regularly performing system suitability tests can also help assess your system's performance and identify potential sources of errors more efficiently.

In the next course topic, we will start with the first troubleshooting topic – baseline disturbances.

Your Shimadzu LC Team

Related Resources

-

-

Auto-diagnostic and Auto-recovery