Helium Shortage Solutions

When it comes to Gas Chromatography (GC) and Gas Chromatography-Mass Spectrometry (GCMS), high purity gas is essential. Helium is the preferred choice due to its inertness, safety, high resolution and speed, and excellent sensitivity, making it the go-to carrier gas for most GC and GCMS applications. However, Helium resources have been depleting over the years, as it is extracted from natural gas and escapes our atmosphere, which has resulted in significant price increases over the past 20 years.

To address this issue, Shimadzu is committed to finding alternative gas options and mitigating the effects of the helium shortage and rising costs.

Select from the options below to learn more about Reducing Helium Consumption or Alternative Gas Options.

Reducing Helium Consumption

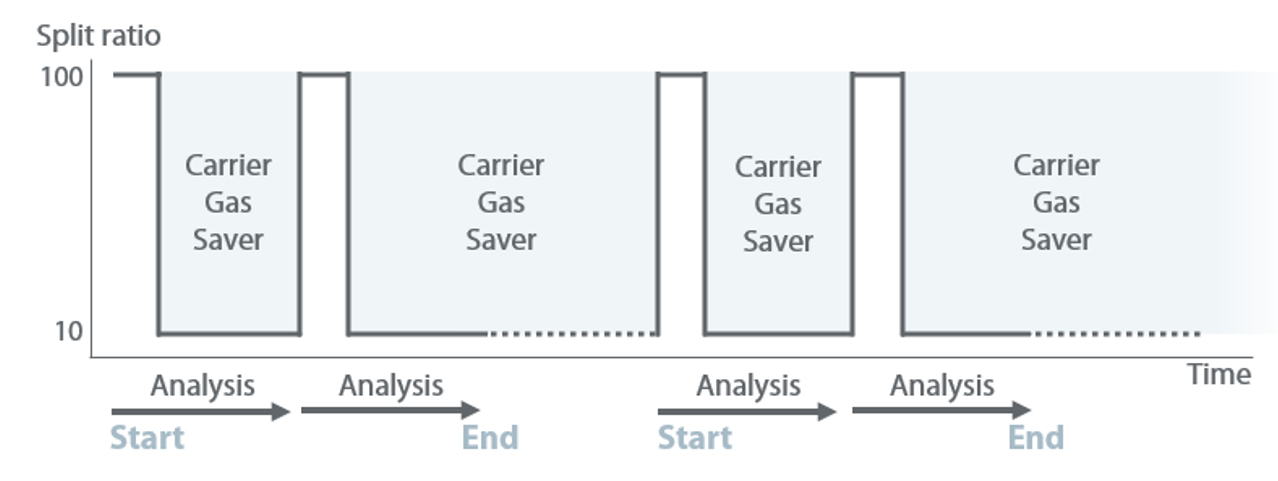

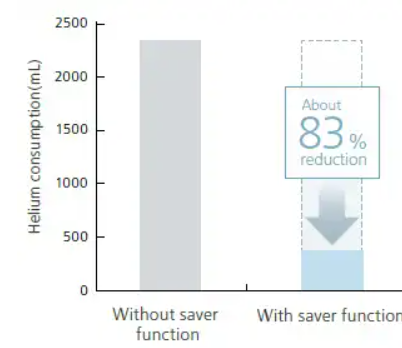

Carrier Gas Saver Function

For split analysis, a large split ratio does not need to be maintained after the sample enters the column. The carrier gas saver function reduces the split flow rate at a specified time after analysis starts until the next analysis starts.

Even after analysis stops, it keeps saving carrier gas until the next batch analysis starts.

*The amount of reduction varies depending on the conditions.

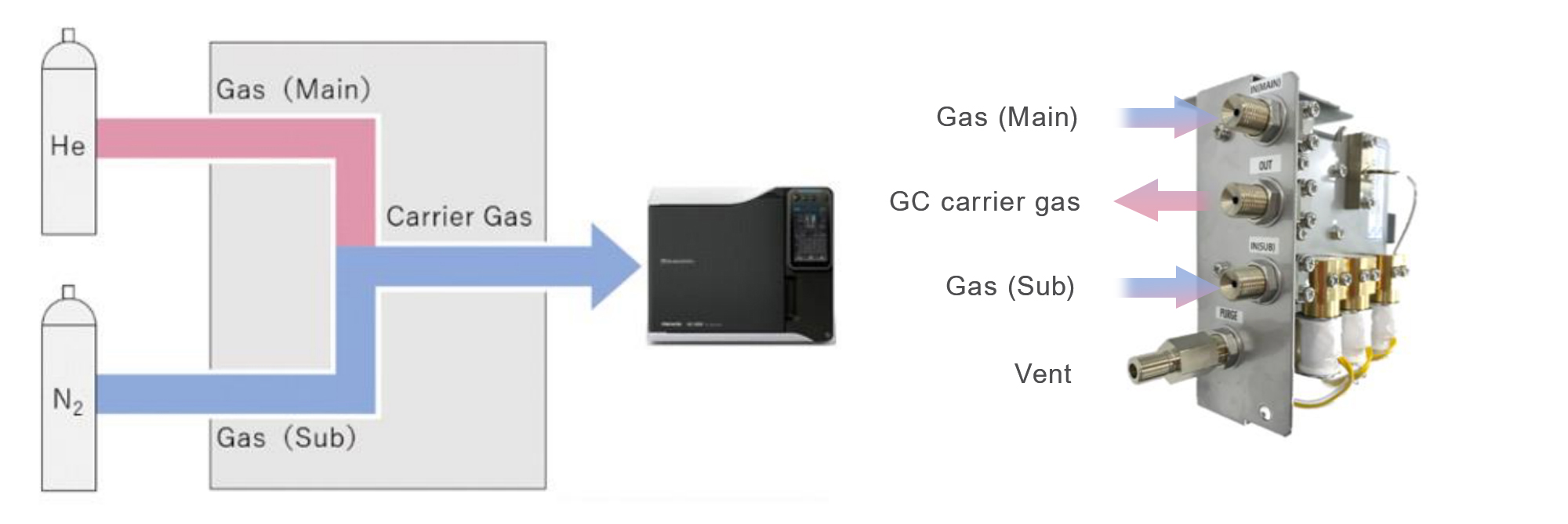

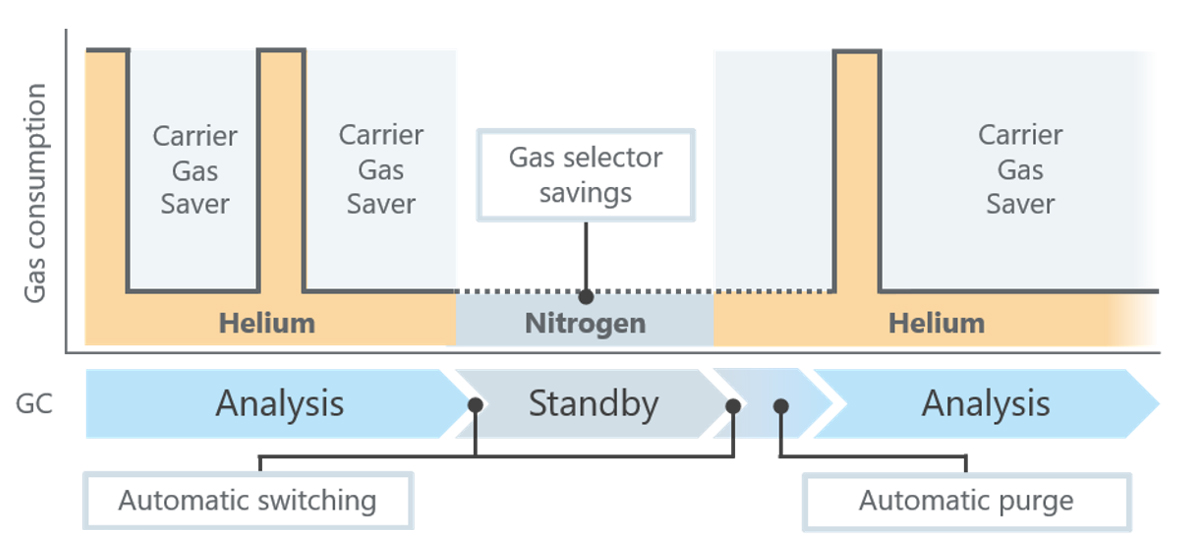

Gas Selector

-

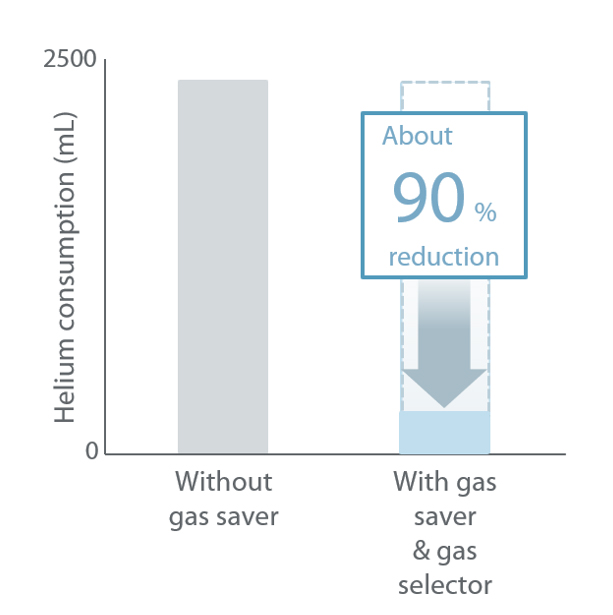

Installing a gas selector significantly reduces helium gas consumption by automatically switching to an alternative gas after analysis, for example Nitrogen.

The system continues to use Helium during analysis - when finished, it switches to alternative gas.

This process is fully automated and has no negative effects on sample running time and quality of the data.

*The amount of reduction varies depending on the conditions.

The gas selector adds additional functionality by automatically switching between methods with different carrier gases, without user intervention.

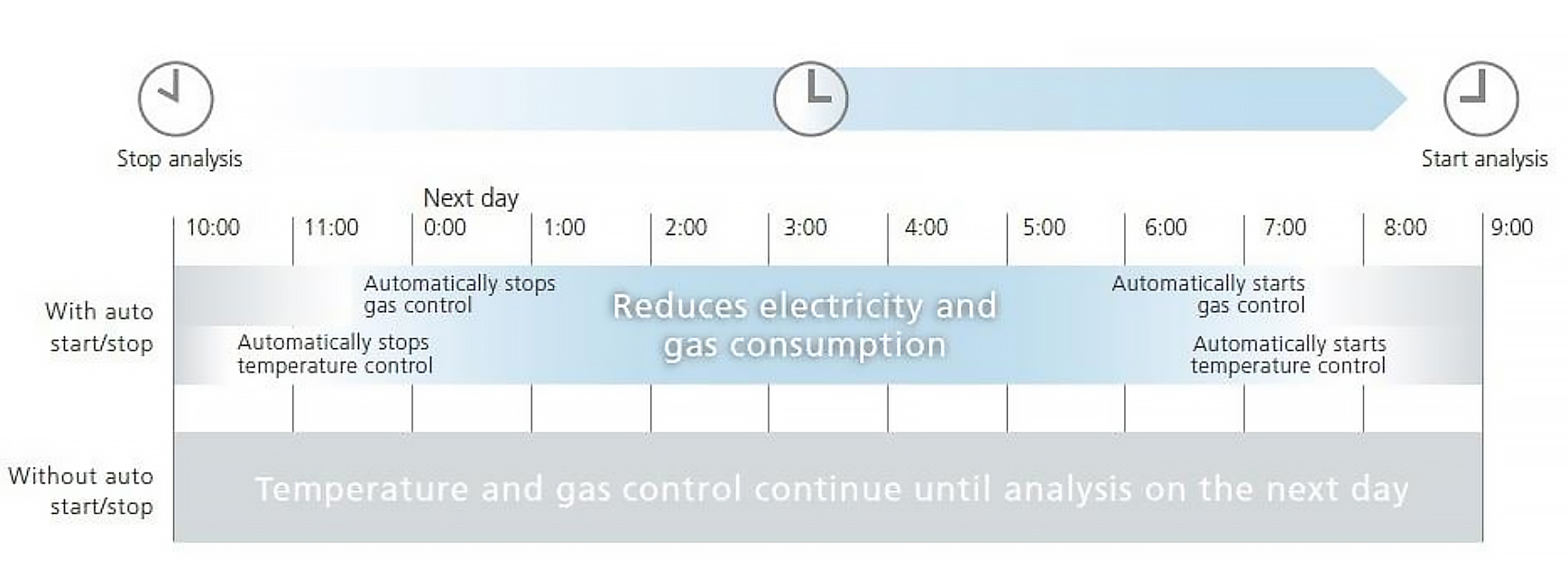

Automated Start/Stop

Shimadzu instrumentation can be scheduled to automatically start-up and shutdown. This prevents the waste of helium when not analysing any samples.

Keep your GC ready at all times. Set your GC to sleep when not in use and immediately wake your GC when you need it. For GCMS systems running is an ‘always on’ environment, the instrument is capable of running in Eco Mode, to automatically minimise gas consumption once analysis is complete.

Narrow-bore Columns

One of the key elements in the reduction on carrier gas consumption, is the move to new narrow bore style columns. These offer higher levels of separation whilst simultaneously, vastly reducing the quantity of gas required. Even whilst using Hydrogen, which typically requires higher velocities, the rate of gas consumed can be significantly reduced with this technology. Shimadzu offer a wide range of narrow bore column for many different applications.

Column flow comparisons:

|

Carrier gas |

Column A |

Column B |

Column C |

|---|---|---|---|

| He at 40 cm/s | 1.23 mL/min | 0.82 mL/min | 0.35 mL/min |

| H2 at 60 cm/s | 1.24 mL/min | 0.83 mL/min | 0.35 mL/min |

Alternative Gas Options

Compare Alternative Gases

| Helium (He) | Hydrogen (H2) | Nitrogen (N2) | |

|---|---|---|---|

| Speed | Good, mid-range analysis speed, best peak resolution with medium linear velocity. | High-speed analysis, best peak resolution with higher linear velocity. | Long run times – peak resolution possible only at low speed. |

| Separation | Good resolution. | Good resolution. | Excellent separation when run at very low speed. |

| Sensitivity | High-sensitivity analysis. | Lower sensitivity, but compound and detector dependent. | Lower sensitivity than H2 and He due to increase in noise. |

| Cost and Availability | Expensive with long lead times. | Low-cost, can use gas generator. | Low-cost and readily available. |

| Safety | Inert and non-flammable. | Explosive/flammable gas. Systems to be fitted with additional safety measures. | Non-explosive gas with high safety. |

| Spectral Impact (GCMS) | No spectral impact. | Compound-dependent, possible reduced library match due to protonation. | No spectral impact. |

| Columns | Up to 0.53 mm column I.D. for GC and GCMS applications. Can be used with packed columns. |

Up to 0.53 mm column I.D. for GC applications and 0.25 mm I.D. or less for GCMS. Can be used with packed columns. |

Up to 0.53 mm column I.D. for GC applications and 0.25 mm I.D. or less for GCMS. Can be used with packed columns. |

Check if your system is compatible with alternative carrier gases here.

Using Hydrogen as a Carrier Gas

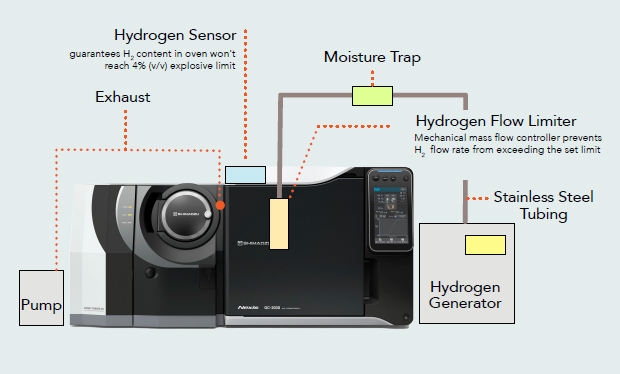

Safety First – Nexis GC-2030 helps to ensure hydrogen carrier gas is used safely.

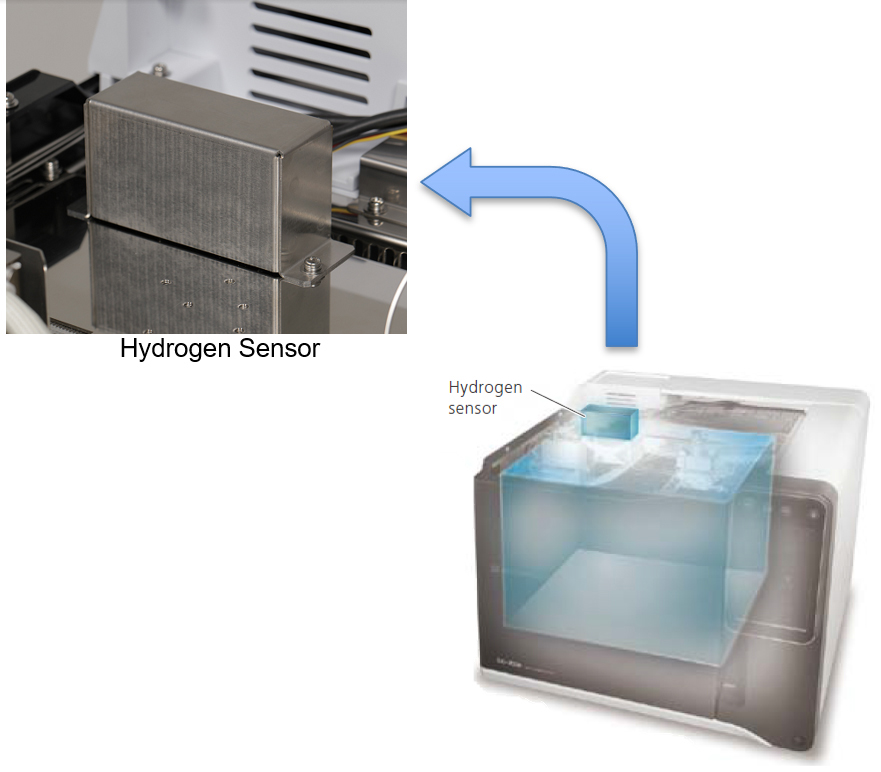

Hydrogen can be a safe and highly effective carrier gas, with correct safety considerations and additional measures. All of Shimadzu’s new GC and GCMS models include a built-in, software-controlled, hydrogen sensor which constantly monitors the hydrogen concentration inside the GC oven and maintains a safe standby mode for early detection of potential leaks. When a leak is detected, the system will automatically shut off gas flow and lower the temperature, switching to a safe standby mode.

Copper piping has a safety risk when using hydrogen as a carrier gas due to hydrogen embrittlement. In Shimadzu GCs, stainless steel material is used in the entire flow path so hydrogen can be used with no additional modifications to the main unit.

-

VIDEO:

Converting GC Methods from Helium to Hydrogen -

Compound Dependent Sensitivity

when Running Hydrogen as Carrier Gas

DOWNLOAD GC-2030/2050 HYDROGEN INFO

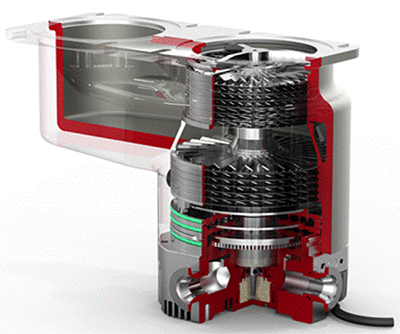

The importance of turbo molecular pump while using alternative carrier gas

-

In the current climate, most GCMS analysis utilises helium as the carrier gas. Shimadzu’s high capacity dual-inlet turbo molecular pump, helium column flows up to 15 mL/minute can be achieved with our single-quadrupole range and up to 10 mL/minute with our triple quadrupole range.

Hydrogen carrier gas offers good separation efficiency, high speed, low cost and is more freely available, but it presents unique challenges in high-grade MS analysis due to its reduced viscosity. However, the vacuum in Shimadzu’s GCMS system can be readily achieved and efficiently calibrated to use hydrogen as a carrier gas thanks to the powerful turbo molecular pump.

In the current climate, most GCMS analysis utilises helium as the carrier gas. Shimadzu’s high capacity dual-inlet turbo molecular pump, helium column flows up to 15 mL/minute can be achieved with our single-quadrupole range and up to 10 mL/minute with our triple quadrupole range.

Hydrogen carrier gas offers good separation efficiency, high speed, low cost and is more freely available, but it presents unique challenges in high-grade MS analysis due to its reduced viscosity. However, the vacuum in Shimadzu’s GCMS system can be readily achieved and efficiently calibrated to use hydrogen as a carrier gas thanks to the powerful turbo molecular pump.

| Maximum column flow | Shimadzu GCMS system |

|---|---|

| 15 mL/min | QP 2020 NX (EI, CI, NCI) |

| 10 mL/min | TQ 8050 NX (and NXNC) |

| 10 mL/min | TQ 8040 NX (and NXNC) |

| 4 mL/min | QP 2010 SE |

Webinars