Liner Selection Guide

Selection by Liner Geometry

The geometry of the liners is usually designed for a specific application:

| Liner Geometry | Injection Technique | Sample Types | Function | |

|---|---|---|---|---|

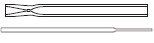

| Straight Liner |

|

Split* SPME Headspace P&T |

General purpose Concentrated samples Gaseous samples Dirty samples (only if wool is present) |

A higher split flow is facilitated, ideal for fast GC and gaseous samples |

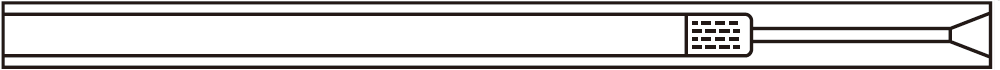

| Tapered / Gooseneck |

|

Splitless* | Trace level Active compounds |

It focuses the sample onto the head of the column and minimizes degradation due to contact with the hot metal parts of the injector |

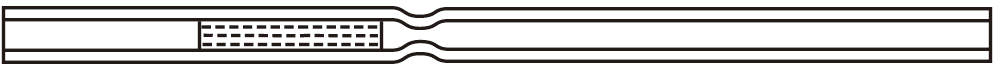

| Focus Liner |

|

Split Splitless |

Dirty samples | Ensures that the wool remains in the correct position, critical for into-wool injections |

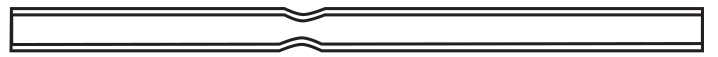

| Direct Tapered Liner |

|

Direct On-column WBI / WBC SINJ |

Trace level Active compounds |

It connects the liner directly to the column and has the same function as tapered liners |

*Most split and splitless liners can be used for both split and splitless applications. However, they perform best for the specified application.

Selection by Evaporation Auxiliary / Packing Material (Wool/Frit)

Purpose and advantage of using wool

The liner wool is a vaporization support that offers several advantages:

It increases the surface area for vaporization, which in turn enables a uniform and fast sample vaporization and helps prevent boiling point discrimination

It protects the column against non-volatile impurities

However, wool is not suitable for active samples since it can increase the number of active sites that can interact with the sample. This can lead to an increased degradation of active compounds, which could translate to peak tailing or the appearance of ghost peaks.

Wool Position

The position of the wool in the liner can have a significant effect in the chromatographic results and may also vary by injector models:

| Near the top - "Into wool" |

|

Especially suitable for autosampler split injections, where high Advantages: Disadvantages: |

|---|---|---|

| Near the middle - "Onto wool" |

|

Especially suitable for autosampler split injections, where high Advantages: Disadvantages: |

| Near the bottom |

|

Especially suitable for autosampler splitless injections, where the residence time of the sample is long. It allows the vaporizing sample to use more liner volume (as the total gas flow in splitless injections is quite slow). |

When setting up the method, and especially if some parameters are critical, like redproducibility or LODS/LOQs, it is recommended to try wool in different positions.

Types of Wool

The first type of wool that comes to mind after hearing “wool” is the textile fibre typically obtained from sheep. However, that is not the type of wool used to fill liners, instead either silica/quartz or glass “wool” is used. Alternatively, frits or baffles can also be used for active compounds.

If needed, wool can be bought separately:

201-47616-01 - 2 g non-deactivated silica/quartz wool

221-48600 - 2 g deactivated glass wool

However, when manually filling the liners with wool it is almost impossible to do so in a reproducible manner. The amount, density and position of the wool can therefore easily vary from liner to liner. Furthermore, the liner deactivation can become damaged in the process. Therefore, it is strongly recommended to buy pre-filled liners with wool, like the ones offered by Shimadzu.

| Liner with Wool |

|

Mainly used for liquid injections |

|---|---|---|

| Liner without Wool |

|

Mainly used for headspace injections |

| Liner with a frit ot baffle |

|

Mainly used for extremely active compounds |

All wool liners are first packed with wool, and then deactivated (see next section), to avoid creating active sites in the liner.

Selection by Liner Deactivation

Some analytes can react with or adsorb to the liner surface, leading to decreased peak intensity and poor peak shape (tailing). To prevent that, most liners are treated with a process called deactivation, which creates an inert surface by covering active sites like silanols.

There are different types of deactivations for different types of analytes:

Standard Deactivation

Suitable for a broad range of polar and non-polar compounds

Tested with EPA 8081B method

Temperature stable up to 400 °C

If not stated otherwise all liners are "standard deactivated"

Base Deactivation

Better recovery of basic compounds

Application examples: amines, basic drugs

Temperature stable up to 350 °C

Siltek Deactivation

Excellent inertness for highly active compounds

Not suitable for bases

Ideal for chlorinated pesticides

Temperature stable up to 380 °C

Silanization

Ideal for pesticides and polar compounds

Suitable for acidic and basic compounds

Not suitable for aqueous samples

Temperature stable up to 320 °C

Selection by Liner Volume

When injecting a sample into the GC, it is important to be aware of the volume injected in relation to the volume of the liner used. If the injected volume is too large, so called “backflash” can occur, leading to several problems:

Contamination of the injection port

Asymmetrical peaks

Appearance of ghost peaks

Not reproducible chromatographic results

To avoid those problems, it is important to inject a lower volume than the liner volume. Typical injection volumes are:

Liquid samples: Approx. 1 - 2 µL

Gas samples: Approx. 0.2 - 1 mL

Typical Liner Volume

| Type | ID [mm] 5.0 mm OD x 95 mm Length |

Volume [µl] | |

|---|---|---|---|

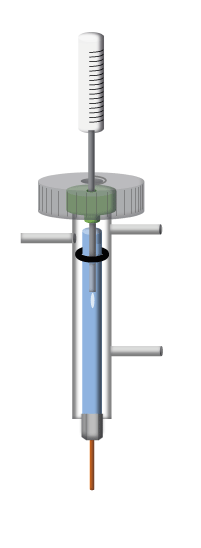

| Splitless: single taper with wool |

|

3.5 | 670 |

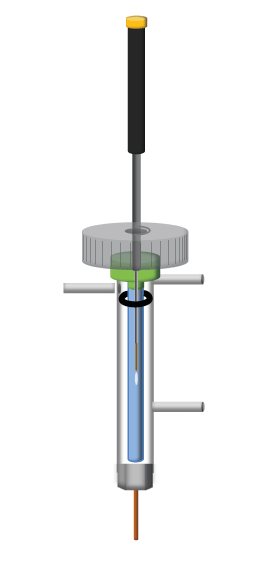

| Split: straight with middle restriction and wool |

|

3.5 | 800 |

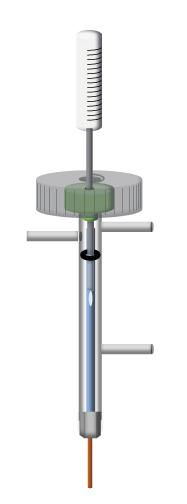

| Split: straight with middle restriction |

|

3.5 | 860 |

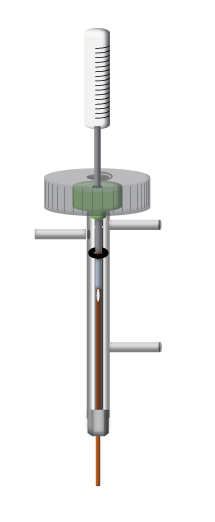

| HS / SPME / P&T: straight through |

|

0.75 | 40 |

|

2.6 | 500 | |

|

3.4 | 860 |

However, especially for liquid samples, the solvent in which the analytes are dissolved is crucial. When the samples are vaporized, and depending on the temperature and pressure of the injector, 1 – 2 µL of injected sample can expand to several hundreds to thousands of microliters!

In table 1, the expansion volume of some solvents calculated for typical injector conditions can be seen.

| Solvent Injected [1 µl] | Expansion / Vaporization Volume [µl] |

|---|---|

| Isooctane | 110 |

| N-hexane | 140 |

| Toluene | 170 |

| Ethyl acetate | 185 |

| Acetone | 245 |

| Dichloromethane | 285 |

| Carbon disulfide | 300 |

| Acetonitrile | 350 |

| Methanol | 450 |

| Water | 1010 |

Table 1. Vaporization Volumes of 1 µL of Various Solvents at an Injection Unit Temperature of 250 °C and a Pressure of 140 kPa.

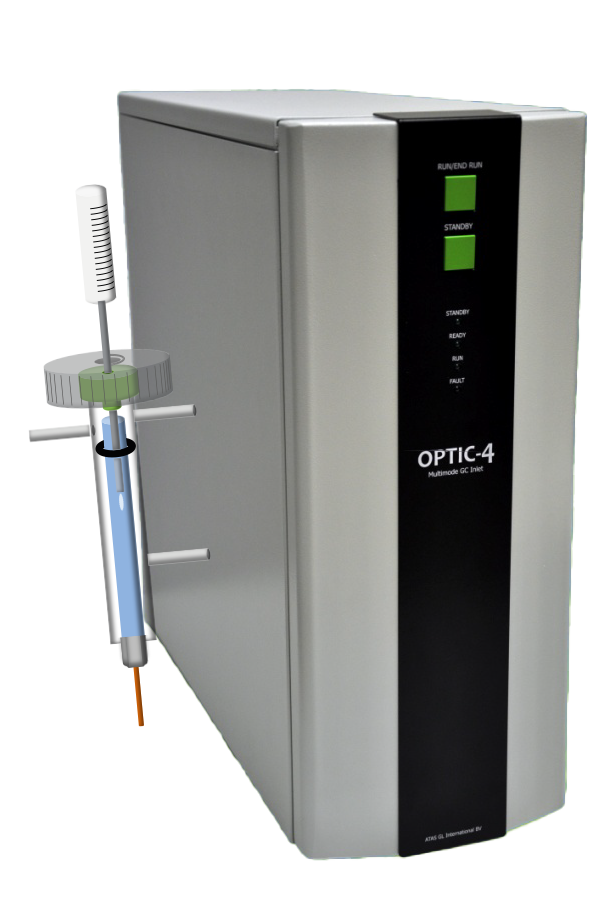

Liner Selection Guide

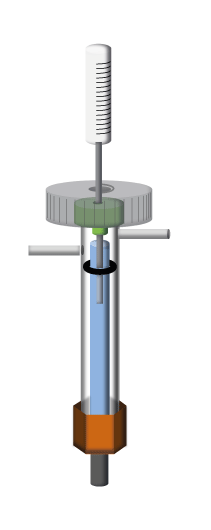

The GC inlet functions as the interface between the syringe and the GC capillary column, where the sample is introduced, vaporized, mixed with carrier gas, and transferred to the column. Shimadzu offers several types of injectors, such as SPL, PTV or OCI, and the corresponding liners for each of them.

There are different aspects that should be considered when choosing the perfect liner:

- Liner geometry

- Evaporation auxiliary /Packing material (wool/frit)

- Liner deactivation

- Injection volume