Hydrogen/Carbon Dioxide Monitoring System

Nexis GC-2030 with 2 detectors & top-mounted valves

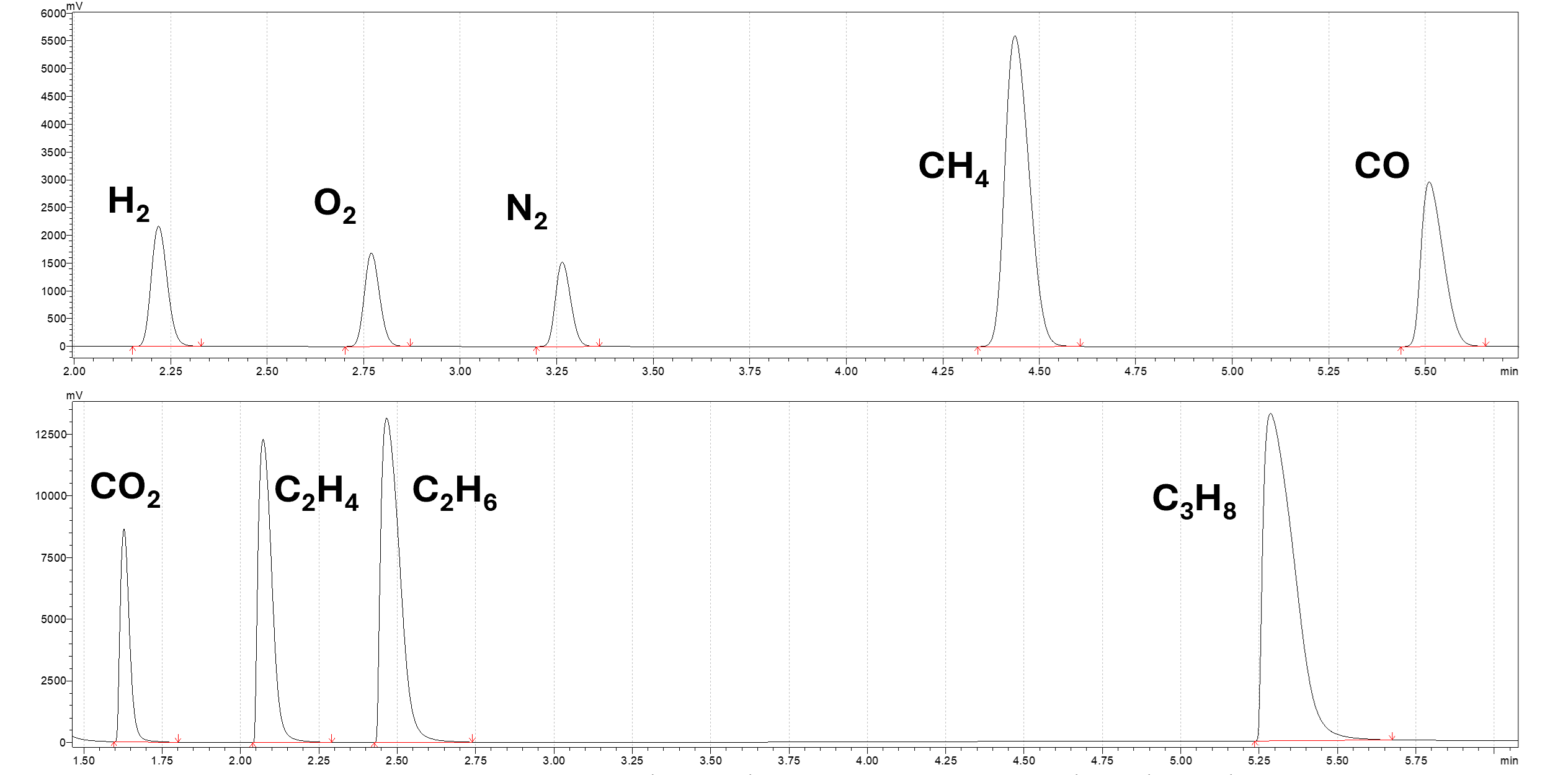

Advancements in H₂ production, carbon capture and CO₂ recycling techniques require robust measurement and analysis. Electrocatalysis, photocatalysis and other methods produce key products including H₂, O₂, N₂, CH₄, CO, CO₂, and valuable hydrocarbons. Shimadzu provides a Gas Chromatography system that facilitates easy qualitative and quantitative analysis of these major components.

System Overview

The chromatograms shown are based on example data. *Other configurations can affect results.

Shimadzu’s flagship GC-2030 configured for H₂/CO₂ Reactor Monitoring offers:

Directly access a GC unit in the Laboratory from a smartphone or a tablet computer

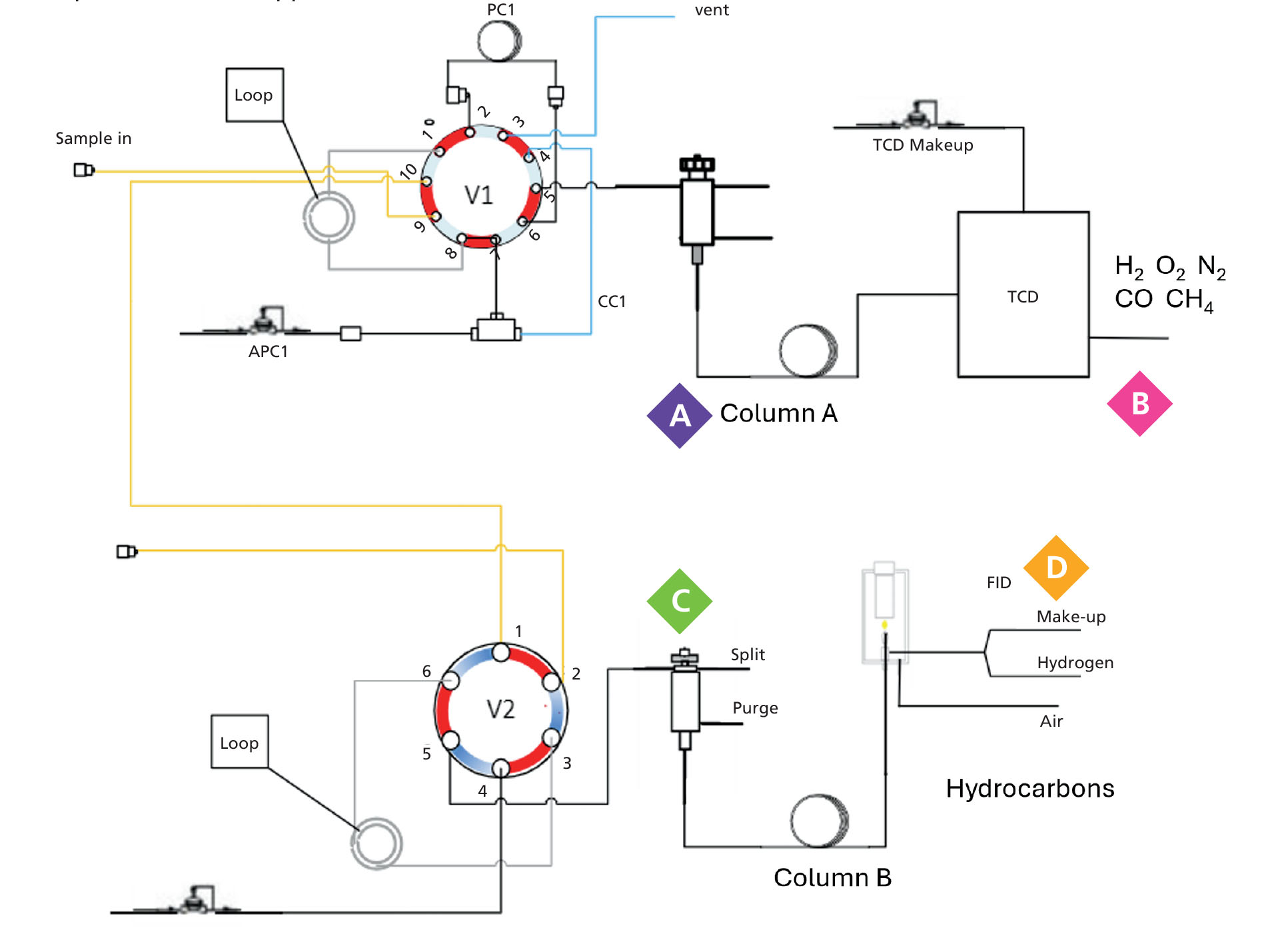

System Schematic

Using a 10-port valve (V1) with backflush capability, using Column A with TCD detection for the analysis of permanent gases including H₂, O₂, N₂, CH₄ CO and CO₂. Expected LODs = 100 ppm (lower achievable, dependent on carrier gas used).

A 6-port valve (V2) injects onto Column B with FID detection for the analysis of light hydrocarbons (chain length C₂ to C₅). Expected LODs = 20 ppm.

Flexible Options and Future-Proofing

![]() Column options depending on analytical requirements

Column options depending on analytical requirements

Column A choice: Molseive 5A for baseline separation of all permanent gases, or Carboxen 1010 to facilitate separation of H₂, O₂, CO, CH₄ and CO₂ on the TCD.

![]() High-sensitivity analysis with BID

High-sensitivity analysis with BID

Use BID (Barrier Ionisation Discharge) detector to improve LODs of H₂, O₂, N₂, CH₄ CO and CO₂ by replacing the TCD.

![]() Liquid Sample analysis (valuable alcohols and hydrocarbons)

Liquid Sample analysis (valuable alcohols and hydrocarbons)

Column B switched out for hydrocarbon capillary column for analysis of liquid samples.

![]() CO₂ detection using methanizing technology

CO₂ detection using methanizing technology

Replace the FID nozzle with Shimadzu’s Jetanizer™ to facilitate CO₂ detection on FID.