High Baseline

GC Troubleshooting Course

6 - Unstable Baseline

7 - Carryover/Ghost Peaks

8 - Fronting Peaks

9 - Poor Peak Resolution

10 - Split Peaks

11 - Response Variability

12 - Retention Time Variability

13 - Course Summary & Test

High Baseline (Column Bleed)

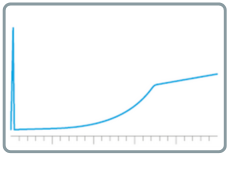

A high or rising baseline in a chromatogram, especially toward the end of a temperature ramp, is often due to column bleed — the gradual thermal degradation of the stationary phase. While some baseline rise is normal, especially during high final oven temperatures, excessive or early baseline elevation can obscure analyte peaks, reduce sensitivity, and compromise quantitation.

Understanding Column Bleed

Column bleed occurs when the stationary phase begins to break down under heat, releasing siloxanes or other degradation products that register as noise. It's most noticeable at higher oven temperatures — often during the hold phase at the end of a temperature ramp. Bleed is more significant in older columns, poorly conditioned columns, or those exposed to oxidative damage.

What to Check and Do

1. Column Conditioning

Improper or insufficient column conditioning is a primary cause of elevated baseline.

Actions:

- For new columns: Increase initial conditioning time and/or temperature (e.g., 2–4 hours at 10°C below max temperature).

- For used columns: Perform overnight bake-out at high temperature to remove built-up residues.

- Always follow manufacturer guidelines for conditioning limits.

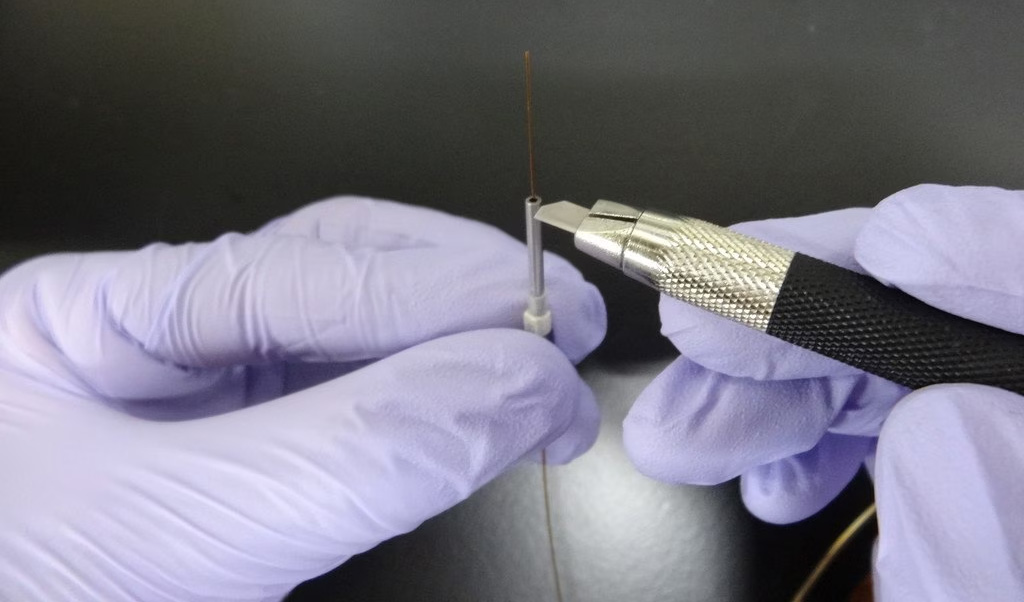

2. Column Trimming and Maintenance

Column ends can degrade or become contaminated over time, especially near the inlet and detector.

Actions:

- Trim 2–5 cm from both ends of the column.

- Reinstall with new ferrules, ensuring clean, square cuts.

- Recondition after trimming.

Pro Tip: Persistent baseline issues in an old column often indicate it’s time for replacement.

Trimming a column is a logical step to follow if you have a persistently high baseline, because the high temperatures needed at the ends of the column can cause gradual degradation and build-up of contaminants.

Click here for the guide on how to trim a column - see Step 4

3. Gas Supply and Filtration

Impurities in the carrier or detector gases (e.g., moisture, hydrocarbons) can exacerbate baseline problems.

Actions:

- Replace carrier and detector gas filters regularly (especially moisture and oxygen traps).

- Ensure high-purity gases are being used (99.999% or better).

- Check for leaks, particularly around the column inlet and septum.

4. Oxidation and Leaks

Oxidation of the stationary phase due to air leaks leads to sudden or severe baseline increases.

Signs:

- Sudden baseline shift on a previously stable system.

- Higher than normal m/z 32 (O₂), 28 (N₂), and 18 (H₂O) in GC-MS.

Actions:

- Check and tighten all fittings, especially column connections and septum.

- Replace worn septa.

- In MS systems: Clean the injector and ion source, and run a manual tune to check for air/moisture contamination.

5. Integration Tips (Short-Term Fixes):

If peaks are still usable but the baseline is high:

- Use blank subtraction to offset the background (not suitable for MS detection).

- Adjust integration parameters to minimize interference (e.g., baseline correction, threshold settings).

Summary - High Baseline Troubleshooting

| Cause | Check | Fix |

|---|---|---|

| Column bleed (normal) | Late ramp hold | Adjust ramp/end temp timing |

| Poor column conditioning | New or reused column | Increase conditioning time/temp |

| Contaminated column ends | Gradual baseline rise | Trim and recondition column |

| Dirty gases or filters | High or drifting baseline | Replace gas filters |

| Oxidative damage | Sudden baseline shift | Check for leaks, replace septum |

| MS air/moisture contamination | High m/z 18, 28, 32 | Clean source, tune, leak check |

Related Resources