Video: Remote Real-Time Mobile Phase Monitoring

HPLC Troubleshooting Course

1 - Basics of Systematic Troubleshooting

2 - Preventive Maintenance Measures

3 - Baseline Disturbances

4 - Pressure Fluctuations

5 - Changes in Peak Shape - Part 1

6 - Changes in Peak Shape - Part 2

7 - Ghost Peaks

8 - Peak Area Fluctuations

9 - Retention Time Fluctuations - Part 1

10 - Retention Time Fluctuations - Part 2

11 - Column Lifespan - Part 1

12 - Column Lifespan - Part 2

13 - Detector Issues

14 - Flow Line Leakage

15 - Course Summary

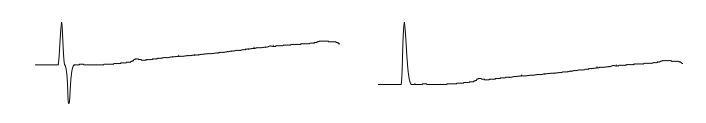

Baseline disturbances are a common occurrence in chromatography and are likely to be found in every chromatogram. However, not all disturbances are problematic as they can be system-related and can themselves be used as a diagnostic tool. The most common is the baseline change associated with the injection itself. When the sample is injected, the time it takes to go through the column without any interactions with the column itself is known as the column dead time.

|

|

|

Peaks at the dead time are very common, mostly due to differences between the sample solvent and the mobile phase. The injection valve switching at the start of the analysis can also cause an injection peak with highly viscous samples. If this is an issue, the sample solvent can be adjusted to match the starting conditions of the method, depending on sample solubility. Even a uniform drift in the baseline can be normal. Every solvent has a UV cutoff, which is the point at which the solvent starts absorbing UV light. When running a gradient at a wavelength below the solvent's UV cutoff, absorption increases along with the solvent concentration, leading to a rise in the baseline. This effect is seen not only in organic solvents like acetonitrile or methanol but also in aqueous buffers or acidified solutions. |

|

|

|

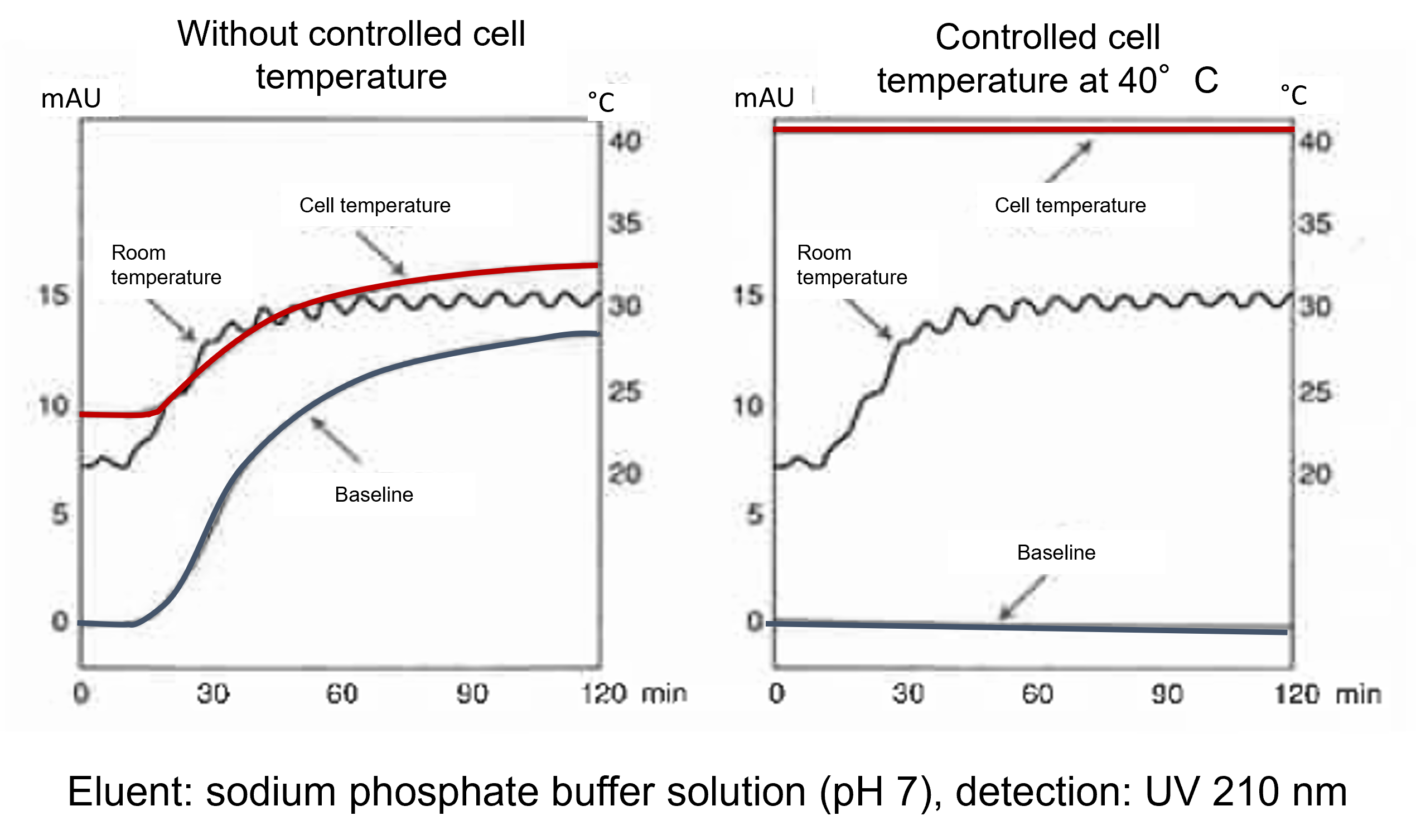

Drifting baselines in chromatography can arise from various factors beyond the inherent absorption of the solvent. Common causes include contamination and temperature fluctuations. Contamination in the flow line or column often leads to erratic baselines, occurring in both isocratic and gradient measurements. As the proportion of organic solvent increases, so does the elution strength, which can release contaminants into the system. Temperature fluctuations are another significant factor, often reflected in the chromatogram. Without proper temperature control of the column or detector cell, the baseline tends to follow room temperature changes with some delay, particularly during extended isocratic runs. Unwanted changes in the eluent composition may also cause baseline drift. These changes can result from issues such as a defective pump or using a pre-mixed mobile phase stored in an unsealed container. |

|

To get to the bottom of the error, we recommend the following procedure: 1. Replace the column with a backpressure capillary 2. Stop the flow 3. Check the detector |

|

|

|

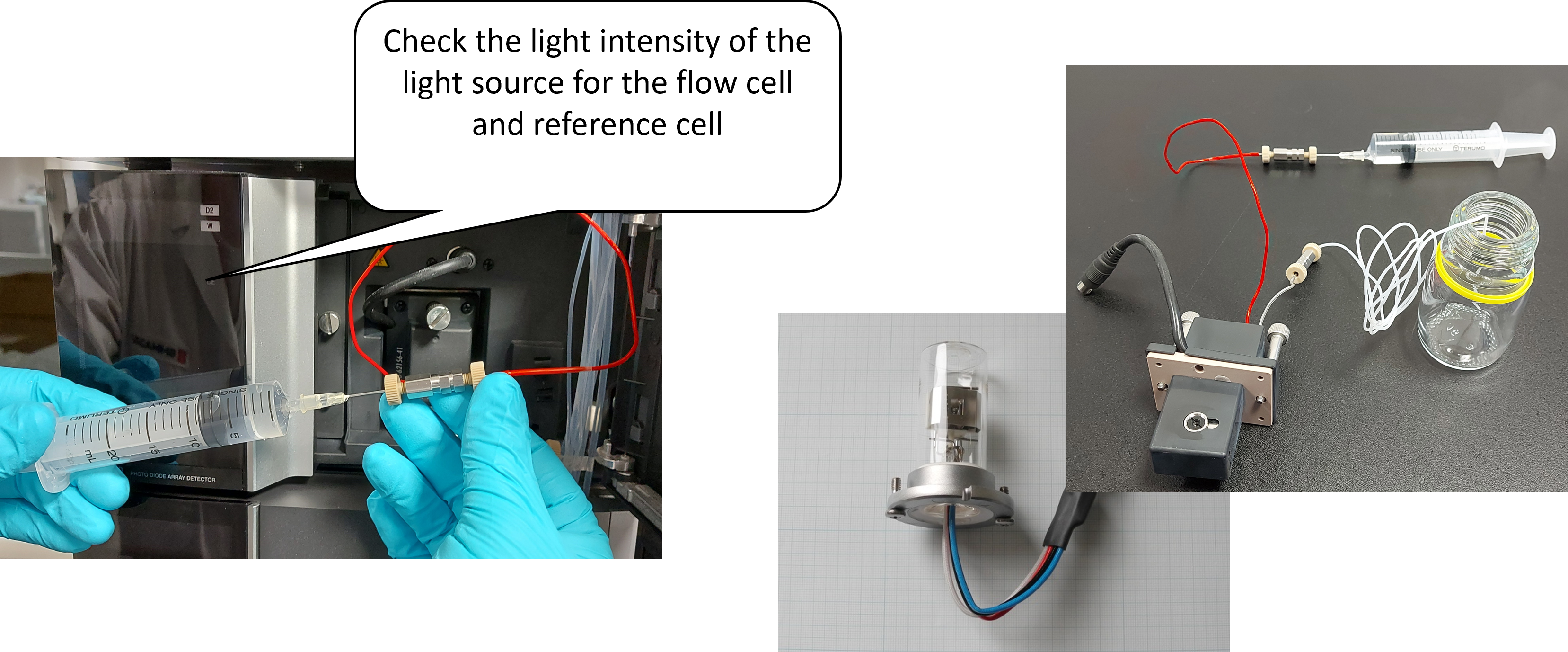

Increased baseline noise can be classified as either regular or irregular. Regular noise often stems from temperature effects, such as excessive column temperature or the absence of proper heating in the detector. Other potential causes including an aging detector lamp that begins to flicker or leaks in the flow line. In contrast, irregular noise often signals system issues like contamination. Air bubbles in the detector can also lead to erratic noise patterns, disrupting the chromatogram's stability. |

|

Recommended procedure to diagnose noisy baselines: 1. Check the pressure 2. Remove the column and record the background level 3. Prepare fresh eluents and record the background level 4. If none of the above apply, check the detector |

Eluents:

Detectors:

HPLC system:

Analytical conditions:

Following these guidelines can reduce the likelihood of fluctuating baselines. Remember, documentation is essential! Knowing the condition of your HPLC system enables quicker problem-solving and more effective troubleshooting.

In the next course unit, we will cover one of the most common issues: pressure fluctuations.

Until then, happy troubleshooting!

Your Shimadzu LC Team

Video: Remote Real-Time Mobile Phase Monitoring