GCMS-QP2020 NX

How a UK-based start-up is aiming to produce carbon-negative hydrogen from biogenic material

INDUSTRY

Environment, Clean Energy, Renewable Energy

KEYWORD

hydrogen, green energy

INTRODUCTION SERVICE&PRODUCTS

GCMS-QP2020 NX

If the potential of hydrogen as an environmentally-benign fuel is to be realised, we need to make it cost-effectively, and move away from the current market dominance of ‘grey hydrogen’ and its unsustainable CO2 emissions. Pyrolysis of biomass has been well-studied as a potentially carbon-neutral way of making hydrogen, but it’s tended to require extensive feedstock processing and high energy use. But now, a UK-based start-up – Wild Hydrogen – thinks they’ve overcome all these problems with a new design of gasification reactor. We talk to them about how they plan to make hydrogen generation carbon-negative, and how they’re using Shimadzu GCMS to understand the composition of their gaseous, liquid and solid products.

Grey, blue, green... and clear

Hydrogen offers the prospect of greening-up heavy transport and industry processes that are otherwise difficult to decarbonise – but only if the method of generating hydrogen itself doesn’t release CO2.

The global hydrogen market is currently worth £100 billion, with key target applications being in sectors that are hard to convert to electrical energy – such as heavy industry, and as a fuel for goods vehicles and shipping.

But there’s a big problem with hydrogen – and that’s the way it’s generated. The market is currently dominated by grey hydrogen, which is made by gasifying fossil fuels, but emits lots of CO2 in the process. Blue hydrogen, generated the same way but with carbon capture and storage, is resource-intensive and so very expensive. And green hydrogen, made by electrolysis of water with electricity from renewable sources, has the same problems and uses scarce materials too, making it uneconomic.

So how can we make hydrogen production both less resource-intensive while at the same time eliminating – or even reversing – the CO2 emissions that typically accompany it? A UK-based R&D company called Wild Hydrogen thinks it has the answer, and they’re using a Shimadzu GCMS to help them on their journey to what they call ‘Clear Hydrogen’.

Adding carbon capture to biomass gasification

Wild Hydrogen was conceived in October 2021, over a coffee-shop conversation between James Milner (now CEO) and Mark Wickham (now CTO). A few months later, the company was founded, and a collaboration was set up with Cranfield University and Helical Energy, to help bring their idea to fruition.

That idea centres on the gasification of biomass into hydrogen and CO2, using a reactor-based process that effectively has the capabilities to remove atmospheric CO2 by capturing it from the produced gas stream. Because the feedstock is not derived from fossil carbon, and because the CO2 can be captured, this method is potentially not just carbon-neutral, but carbon-negative. So at a stroke, it would generate the hydrogen needed for tomorrow’s economy while also (in effect) using photosynthesis to do the difficult work of pulling from the atmosphere the CO2 that’s driving climate change.

Straw, wood pellets and compost – just three of the biomass feedstocks that the team at Wild Hydrogen have been investigating for hydrogen generation.

With their work still in the development phase, the details of their reactor and the process they use are not yet in the public domain. But suffice to say that they’ve made three major advances that have enabled them to make the production of hydrogen economically viable:

• Minimal pre-preparation: Their method does not require extensive processing of the feedstock prior to introduction into the reactor. Specifically, the biomass can have a water content as high as 50 wt%, and doesn’t need to be milled to a uniform size, boosting the overall cost-effectiveness.

• Reduced heating costs: By careful reactor setup and workflow, they’ve been able to reduce the amount of time and energy needed to raise the biomass to the temperature and pressure needed for gasification.

• Minimal use of resources: By using only readily-available metals and ceramics, their approach eliminates the need for scarce or hazardous rare-earth metals. Unlike some other methods, large amounts of water are also unnecessary, further enhancing the method’s green credentials.

To demonstrate that their concept works in practice, the team at Wild Hydrogen has been busy over the last two years developing a series of prototypes, which have steadily increased in scale, efficiency and robustness. Their reactor design has also been shown to work with a variety of different biomass feedstocks, including bioenergy crops, forestry residues, macro-algae as well as waste products such as oversized compost. The reactor even gives good results with waste plastic!

Assessing hydrogen purity… and byproduct composition

The result of Wild Hydrogen’s biomass conversion process is a gas that is rich in hydrogen, but which also contains carbon dioxide, carbon monoxide, methane, and a range of other volatile compounds at low concentrations. But to make their reactor a viable commercial proposition, they need to produce gas that is high in purity, and have an analytical system that can provide evidence of that purity.

But the purity of their hydrogen, important as it is to the company, isn’t the end of the story. The gasification process also results in solid biochar, and a small amount of liquid bio-oil (or tar). Understanding the chemicals present in these products is essential for working out the processes that are happening inside the reactor, and so optimising the yield of hydrogen. But the team also has an eye on keeping the whole process as ‘circular’ as possible by re-using these byproducts – for example, the biochar could be used for CO2 capture, while the bio-oil could be added back into the feedstock, to generate more hydrogen.

Understanding the composition of all these gases, liquids and solids needs a versatile analytical setup – and that’s where Shimadzu comes into the story.

Developing a bespoke analytical system

The conversation with Shimadzu started early on, following a meeting at a laboratory tradeshow event. The team at Wild Hydrogen was particularly excited by the possibility of covering the whole range of gaseous analytes in one run, and the decision to go with Shimadzu was cemented after realising the value of Shimadzu’s consultative approach and once they’d seen first-hand the capabilities of their instrumentation.

Early on, it was clear that a custom system was going to be needed, because the conditions within the reactor precluded using on-line sampling, while the desire from Wild Hydrogen to accommodate analyses of non-target compounds in liquid and solid fractions, as well as gas samples, meant that MS detection (rather than FID, TCD or BID) was going to be needed.

Off-the-shelf systems for this kind of work aren’t readily available, but Shimadzu specialise in modifying standard GCMS instruments for special applications, so they set to work on devising a setup for Wild Hydrogen. The result was a bespoke system based on the Shimadzu GCMS-QP2020NX, with the setup for gas analysis involving two sample loops filled from a canister or gas bag. The loops are connected to PLOT columns that between them provide excellent performance for hydrogen, carbon dioxide and the other permanent gases expected. Meanwhile, the use of an MS detector means that the system can detect and identify the volatile organic compounds expected from the biochar and bio-oil, with separation of the mixtures achieved by simply switching out one of the PLOT columns for a capillary column.

The system was installed in summer 2023, at roughly the same time that Dr Michael Sims joined Wild Hydrogen as a Research Chemist. With his background in organic geochemistry, Michael was familiar with using pyrolysis to study organic residues in rocks, so transitioning to studying the breakdown products of biomass in the company’s reactors using the new GCMS was a natural step. In his current role, he’s working on their fourth reactor prototype, nicknamed ‘Mini’, with a focus on maximising energy efficiency and recovering heat.

Versatile instrumentation and responsive staff

Having been using the Shimadzu system for nearly a year, Michael says he’s very happy with it: “What we like about it is its versatility – we can adapt the setup to run a number of different analyses, and it’s very simple to switch between them. If we’d just got a gas analyser or an off-the-shelf GCMS system, we wouldn’t have that ability”.

And having an in-house system means he can respond quickly to internal requests, he explains, because they don’t need to rely on expensive and time-consuming outsourced analyses. “With our Shimadzu system, I can run a gas analysis, and within 10 minutes I can tell the rest of the team what the composition is. It’s our laboratory workhorse, and it’s fair to say that it’s become a vital part of our operations”.

The level of service they’ve received from Shimadzu has been important to Michael and the rest of the team at Wild Hydrogen, he adds: “Getting the system up and running was seamless, and the aftercare has been very positive too – everyone’s really approachable, and if we have a question, however small, we can just get in touch”.

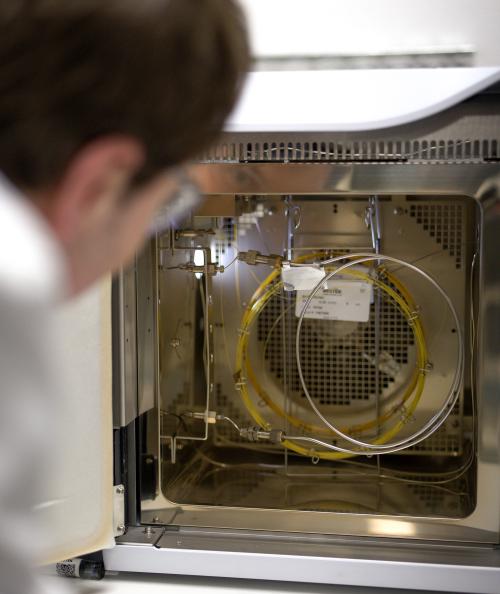

Dr Michael Sims inspects the column oven of the custom Shimadzu GCMS, showing in the foreground the guard column, and two of the compound separation columns (yellow and orange). The use of multiple columns means that the total flow of gas to the MS is higher than normal – but this is easily handled with the system’s high-capacity dual-phase turbo pump, capable of tackling up to 15 mL/min without loss of sensitivity.

Conclusion: Leading the way in sustainable hydrogen

Currently, says Michael, they’re embarking on projects to investigate the best conditions for cleaning up their gases. The first aspect is downstream technology to separate out the CO2 from the hydrogen, followed by purification equipment.

For the hydrogen, Michael says a lot will depend on what is requested by the purchasers of their gases. But, he says, “we’re basically aiming to generate hydrogen of sufficient purity suitable for the fuel cells used in hydrogen-powered vehicles”.

He also explains that, to ensure that the CO2 they separate out is a suitable purity for carbon storage, they’ll need to check that it’s free from oxygen and other contaminants – another aspect of their workflow that their Shimadzu system will no doubt prove very useful for, he says.

So, in conclusion, Wild Hydrogen are getting a lot of value from their Shimadzu GCMS. Michael says: “Having a versatile analytical system that provides quick sample turnaround has not only accelerated our R&D, but it will be integral to verifying the purity of the gases we produce, too”. And those benefits will be crucial to helping Wild Hydrogen lead the way in cost-effective, sustainable generation of ‘Clear Hydrogen’ – a win-win for industry and the climate.

Dr Michael Sims - Research Chemist

*Affiliates and titles of the interviewee are current as of the time of reporting.

Wild Hydrogen

URL

https://wildhydrogen.com/