Summary and Exam

LCMS Troubleshooting Course

Course Conclusion

Thank you for participating in our online course, Troubleshooting in Liquid Chromatography Mass Spectrometry. We hope this course has equipped you with practical tools to maximise system uptime, prevent errors, and quickly diagnose and resolve issues.

In the past 14 course sections, we have covered a wide range of potential error sources. However, troubleshooting is an ongoing learning process, and new challenges may arise that were not addressed here. To effectively tackle unexpected issues, always follow the key troubleshooting principles:

- Change only one variable at a time to systematically identify the root cause.

- Take a step-by-step approach to avoid unnecessary modifications and confusion.

- Document your process to build a reference for future troubleshooting and improve efficiency.

By applying these strategies, you will develop a deeper understanding of your LCMS system and gain valuable hands-on experience.

Preventing Errors: Key Takeaways

- Regularly perform cleaning protocols for the ionisation source to remove residue and maintain performance

- Clean up samples where possible to prevent unwanted matrices entering the mass spectrometer

- Tune the MS to obtain an acceptable quality spectrum which will improve accuracy and peak shape. This will assist with mass resolution and sensitivity.

- Never leave buffers in the system. Rinse them out with pure water (depending on the column) or maintain a low flow rate to prevent salt precipitation.

- Use a mediator solvent when switching between immiscible eluents or between buffers and organic solvents. The mediator should be compatible with both phases to ensure a smooth transition.

- Keep thorough documentation. Maintain column logs, maintenance records, and usage lists to always have a clear overview of your HPLC’s condition.

- Perform regular system tests to monitor the health of your system and column, ensuring you have a reliable baseline for troubleshooting if issues arise.

- Control system temperature. Whether for the column, detector, or autosampler, stable temperature conditions are critical for reproducibility and performance. Temperature fluctuations can significantly impact various components.

- Immediately discard defective spare parts to prevent accidental reuse, which could lead to further issues.

- Rinse your system and column regularly to remove contaminants and extend their lifespan.

- Handle your column with care. It is the heart of your system, along with the eluents. Avoid physical shocks, sudden pressure changes, and operation outside the manufacturer’s specifications.

- Standardize eluent preparation procedures to ensure consistency and reliability in your analyses.

We have more resources on our website or on our YouTube Channel.

To receive your completion certificate, test your knowledge with the quiz below.

A passing score is 75% of the total available points.

Please note that certificates are issued periodically and may take 2-3 weeks to arrive.

Thank you again for your participation! We wish you the best of luck on the final test.

Your Shimadzu LCMS Team

Related Resources

-

-

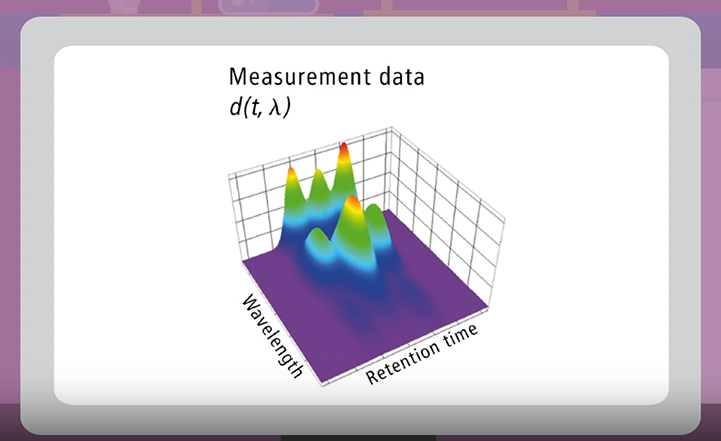

Watch short videos explaining analytical intelligence features of Shimadzu HPLC systems

-