Unstable Baseline

GC Troubleshooting Course

6 - Unstable Baseline

7 - Carryover/Ghost Peaks

8 - Fronting Peaks

9 - Poor Peak Resolution

10 - Split Peaks

11 - Response Variability

12 - Retention Time Variability

13 - Course Summary & Test

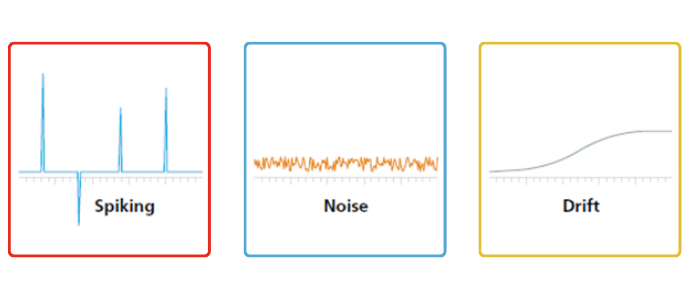

Unstable Baseline (Spiking, Noise, Drift)

An unstable baseline can take three main forms Spiking, Noise and Drift:

- In contrast to the solvent peaks that you would expect in any solvent-injected GC run, spiking is the presence of unexpected peaks. These are due to either contamination or a detector fault, such as loose electrically connect.

- The presence of excessive noise on the baseline is a very common issue, and which is more apparent in low-concentration samples. However, what’s more important to take notice of the signal-to-noise ratio of target compounds and take action should any unexpected changes occur.

- Baseline drift is closely related to the high baseline problem that we covered in Week 2, but in this case, drift can occur anywhere through the run, not just at the end. This can be compensated for by adjusting the integration parameters to account for drift.

The cause of many of these problems is contamination within the system, the source of which can be determined using a step-by-step approach.

Check the following parts in turn:

1. Carrier gas – If you haven’t done so already, leak-check the system, confirm the purity of your gas supplies, and check that the flow and pressure controllers are functioning correctly. If those are OK, then replace the carrier gas and/or detector gas filters.

2. Septum and inlet – Septum coring can be a source of contamination, and pieces of the septum can break off leading and collect in the inlet liner. Clean or replace the necessary parts and ensure that regular maintenance is scheduled. These guides demonstrate how to replace the septum and liner — you may find them useful.

3. Column – The first step is to recondition the column. Then try trimming the column by a few centimetres at both ends (because the ends of the column are always heated to a higher temperature, they can degrade more quickly than the rest). For the column trimming guide click here (see step 4 in the provided link).

4. Detector – First, ensure that you’re allowing enough time for detector temperatures and flows to equilibrate. If that doesn’t solve the issue, then clean the system and ensure that your maintenance is being carried out as scheduled.

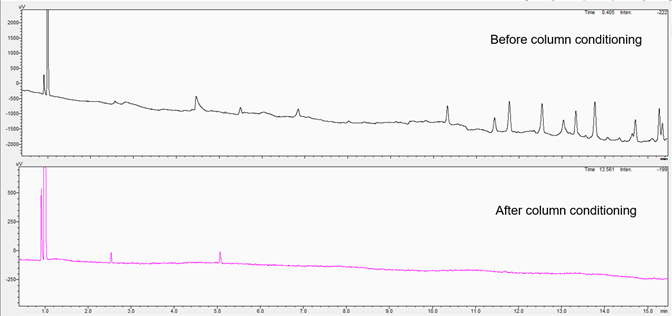

Chromatograms showing comparison before and after removal of contamination

Contamination is a common cause of baseline problems, and in this case of column contamination in the higher black chromatogram,

a problem with peaks was resolved by conditioning the column at 10 degrees below the column’s maximum operating temperature

to give the pink trace and remove the contamination. In this example, the peaks of interest were two pink peaks at

2.5min and at 5min that were not visible before removal of contamination.

A less common cause of high baseline is oxidation of the stationary phase. This usually results from a leak in the system (column or septum) and might be indicated by a sudden change in baseline in a system that had currently been behaving well.

So, if your column is an older one, trimming or replacing it is an obvious course of action, along with a check of the column connections and septum. If you’re using MS detection, then you can perform a manual tune and look out for the presence of suspiciously large signals at m/z 18 (H2O), 28 (N2) and 32 (O2).

Related Resources