Preventive Measures

LCMS Troubleshooting Course

1 - Basics of LCMS Systematic Troubleshooting

2 - Preventive Maintenance Measures

3 - Pressure Issues

4 - No Peaks Detected

5 - Changes in Peak Shape - Part 1

6 - Changes in Peak Shape - Part 2

7 - Ghost Peaks

8 - Peak Area Fluctuations

9 - Baseline Disturbances

10 - Retention Time Fluctuations - Part 1

11 - Retention Time Fluctuations - Part 2

12 - Changes in Chromatographic Resolution

13 - Changes in MS Response

14 - Undesired Fragmentation & Ion Source Settings

15 - Course Summary & Quiz

Preventive Measures

The second part of the Troubleshooting course focuses on preventive measures that can extend the lifespan of your equipment. By consistently applying these practices, you will experience fewer issues in your lab, ultimately reducing the error rate. We will cover both optional and essential actions that can inevitably lead to errors if neglected.

1. Preventing Blockages

- Avoiding small microparticles in your HPLC system is crucial, as they can lead to clogging of the capillaries, valves, and separation columns – issues that may require costly column replacements. Therefore, it is important to consider your sample preparation and filter samples to remove particulates e.g. using a syringe tip filter. It is essential to treat standards in the same manner as samples; certain filter materials may absorb analytes, leading to falsely low results. This can also soil the source and internal components which will decrease the number of ions entering the mass spectrometer thereby decreasing the sensitivity.

- Extra care should be taken with purely aqueous eluents in the solvent bottle, as they can promote the growth of microorganisms, which may lead to blockages. Regularly renewing the eluent is recommended to mitigate this risk.

- When using buffers, it is important to consider their compatibility with organic solvents. At high concentrations, some buffers may precipitate, leading to blockages in the system. Preliminary tests on compatibility are therefore recommended.

- Only employ volatile additives and buffers which can be ionised within the source. Non-volatile additives such as phosphates will cause the ion source to block with significant damage.

2. Flushing

- Contamination of the flow line or the column can have a significant impact on chromatography. If the column is not clean, the back pressure can increase substantially, or the selectivity of the phase can change permanently.

- For samples that are highly matrix-bound, incorporating a cleaning step in every method is essential. If the column becomes heavily contaminated, connect it directly to the pump for flushing to prevent contaminants from reaching the detectors. Additionally, the flow line can be flushed with appropriate solvents without the column, by utilising a backpressure capillary.

3. Degassing

- Dissolved air in the mobile phase has a significant impact on baseline stability and the signal-to-noise ratio. Additionally, excess dissolved air can lead to the formation of air bubbles, much like releasing pressure from a water bottle. Therefore, using an online degasser is highly recommended for optimal performance. Trapped air bubbles in the pistons can cause considerable ripple in the pressure trace which can cause poor reproducibility in chromatographic results. Should this happen, the system should be purged to remove the trapped bubbles, or use a solvent such as 2-propanol to help remove stubborn air bubbles.

4. Temperature Control

- Temperature is a major factor in chromatography, as it significantly affects both the separation and detector sensitivity. As the column temperature rises, the viscosity of the eluents decreases, leading to lower pressure, and altered retention times. The same applies to the detectors. Depending on the temperature, the sensitivity changes, and fluctuations in room temperature also leads to fluctuations in the baseline. Therefore, if possible, you should keep your system temperature controlled. This can be achieved through a column oven, and the right choice of installation location. Avoid placing the system in areas with a draft or in direct sunlight.

5. Detector Settings

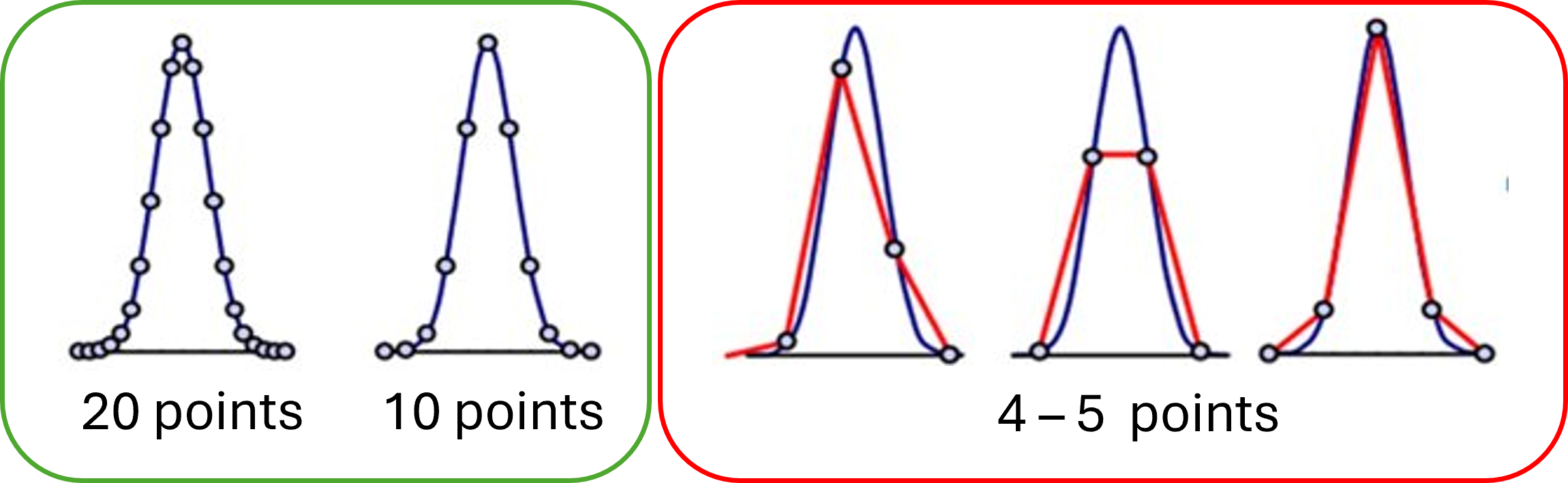

Fig. 1 Illustration of how the number of data points can affect how the peak is described

- Accurate setting of the data acquisition rate of the detector is often overlooked. An improper setting can lead to significant variation in peak area. Firstly, the right polarity must be selected for the analytes of interest. This might require a compromise for large mixtures of compounds. Optimising the ion transitions will allow for greater detection limits and peak confirmation by adjusting the voltages, gas flow and temperatures. It is also important to apply an appropriate dwell time – this is the amount of time the instrument collects data for a specific ion transition. An increased dwell time will improve sensitivity but at the cost of decreasing the number of transitions that can be monitored in a given cycle, and an increased datafile size. However, if there are hundreds of analytes in an unknown mixture, a wider dwell time will allow for the capture of more peaks. As with most aspects of chromatography, there is a compromise to be made.

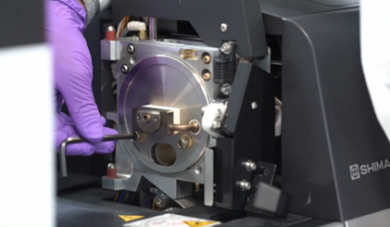

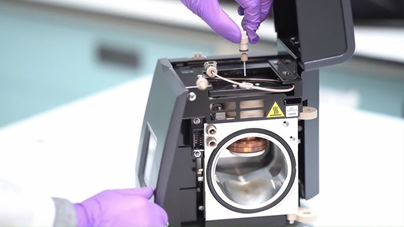

6. Ion Source Maintenance

- The ion source is a major cause of contamination, where the mobile phase and sample are converted into ions. In addition to using MS quality solvents and additives and sufficient sample preparation, it is important to routinely clean the ion source using appropriate procedures to remove soiling. This is typically performed using methanol or isopropanol to remove the soiled areas with a lint free cloth. Certain components can also be sonicated in methanol to facilitate the removal of the contaminants.

-

-

7. Perform a System Suitability Test

- A system suitability test mixture (SST) allows you to benchmark your whole system when it is working optimally. If the results begin to change, such as a decrease in sensitivity or a change in retention time window, this could indicate the system is no longer working as it should and requires some attention. This could involve cleaning the ion source, ion guide (such as Shimadzu's proprietary Qarray) and lens to improve the sensitivity, or ensure the pumps are working effectively, for example. The system should be tuned on a regular basis and after every clean to ensure the precision and accuracy of the detector.

By following these preventive measures, you can proactively avoid many common errors in LCMS. Regularly performing system suitability tests can also help assess your system's performance and identify potential sources of errors more efficiently.

In the next course topic, we will start with the first troubleshooting topic – baseline disturbances.

Your Shimadzu LCMS Team

Next week's units will be delivered directly to your inbox according to your weekly schedule, but if you can't wait and would prefer to continue with the course now, click here.

Related Resources

-

The Nexera series is a family of HPLC systems that marries AI and IoT enhancements to set new industry standards.

-

Auto-diagnostic and Auto-recovery