Intelligent Peak Deconvolution Analysis (i-PDeA II)

HPLC Troubleshooting Course

6 - Changes in Peak Shape - Part 2

7 - Ghost Peaks

8 - Peak Area Fluctuations

9 - Retention Time Fluctuations - Part 1

10 - Retention Time Fluctuations - Part 2

11 - Column Lifespan - Part 1

12 - Column Lifespan - Part 2

13 - Detector Issues

14 - Flow Line Leakage

15 - Course Summary

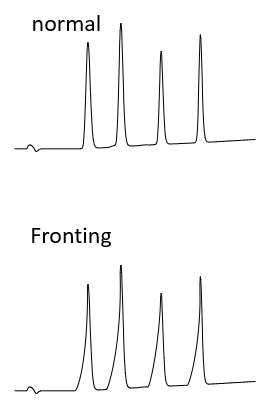

In the second part of changes in peak shape, we explore the possible causes for different peak shapes - fronting, tailing and peak broadening.

Fronting generally refers to an asymmetry of the peak, where a peak is steeper at the end than at the beginning - similar to a shark fin. If fronting gradually increases, in most cases, a defective column is the cause. The stationary phase can be damaged due to normal aging or operating the column outside the specifications (e.g. temperature or pH). In this case, only replacing the column and adjusting the chromatographic conditions will help.

However, column overloading also leads to fronting of the peaks. If too much sample is injected, all active sites at the column head are occupied, and the remaining sample flows past the occupied sites with less interaction. If you are bound to high injection volumes, a column with a larger inner diameter or higher capacity can help.

Another reason for peak fronting can be an incompatible sample solvent or poor sample solubility with the mobile phase. In this case, only changing the sample solvent will help. A too low column temperature can also cause fronting.

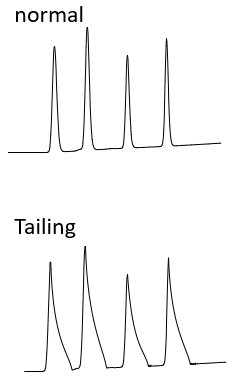

Tailing, along with broadening, is the most common peak shape change and is the exact opposite of fronting. The rising edge of the peak has a greater slope than the end, often caused by the analyte having more than one mechanism of retention on the column.

When using a standard reversed phase column, usually analyte retention is obtained through hydrophobic interactions, but the interaction of basic analytes with the free silanol groups can lead to tailing. As silanol groups are acidic, it's possible to minimise interactions with the analyte by lowering the pH of the chromatographic conditions. If that isn't possible, try replacing the column with a deactivated column such as a polymer column or one with good endcapping. Some column manufacturers offer special columns for the analysis of strongly basic substances.

A damaged column or incorrect analysis conditions, such as an incorrect pH value of the mobile phase, can also lead to tailing, as with fronting.

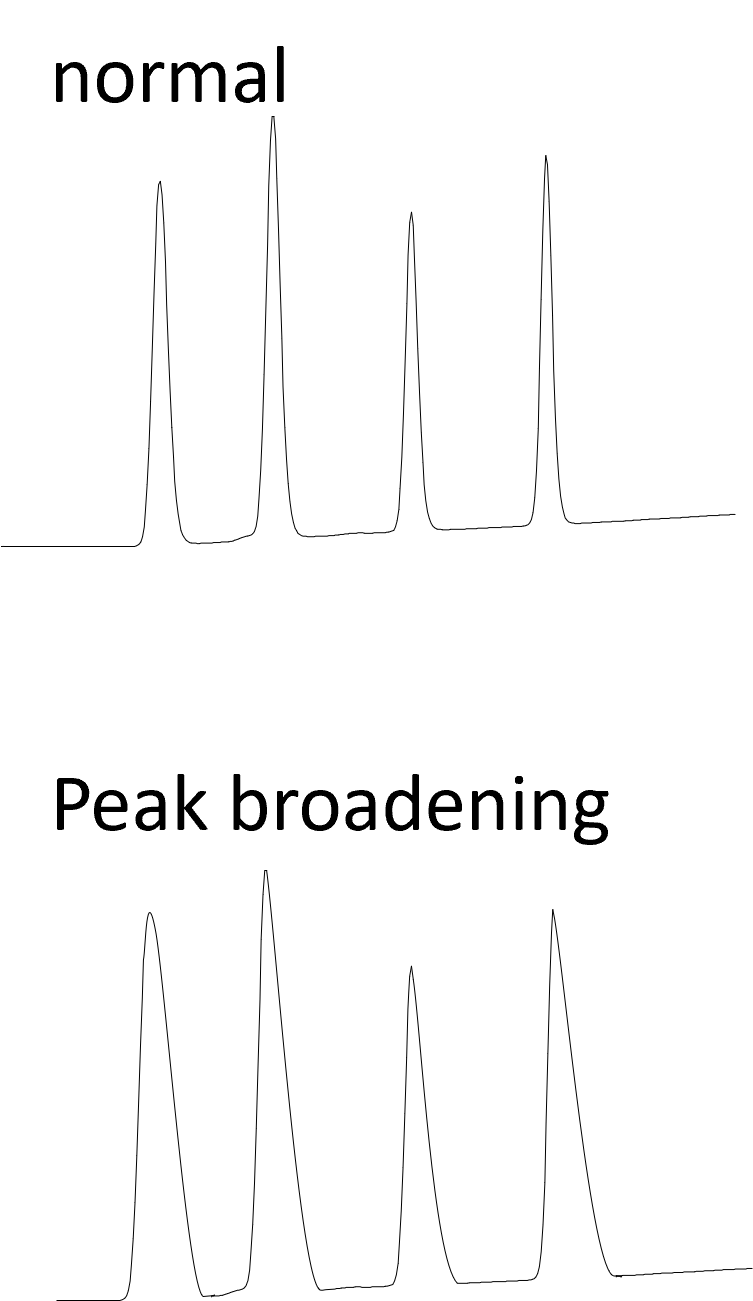

In the previous section on changes in peak shape, we discussed detector settings. A detector response that's set too high can contribute to peak broadening. However, it's important to note that normal column aging is also a common cause.

If peak broadening occurs due to dispersion in the injection valve, a "sandwich injection" with small air bubbles can help reduce this effect. Another cause of dispersion can be due to using capillaries with too large diameter or the unintentional introduction of dead volume due to improperly tightened connections.

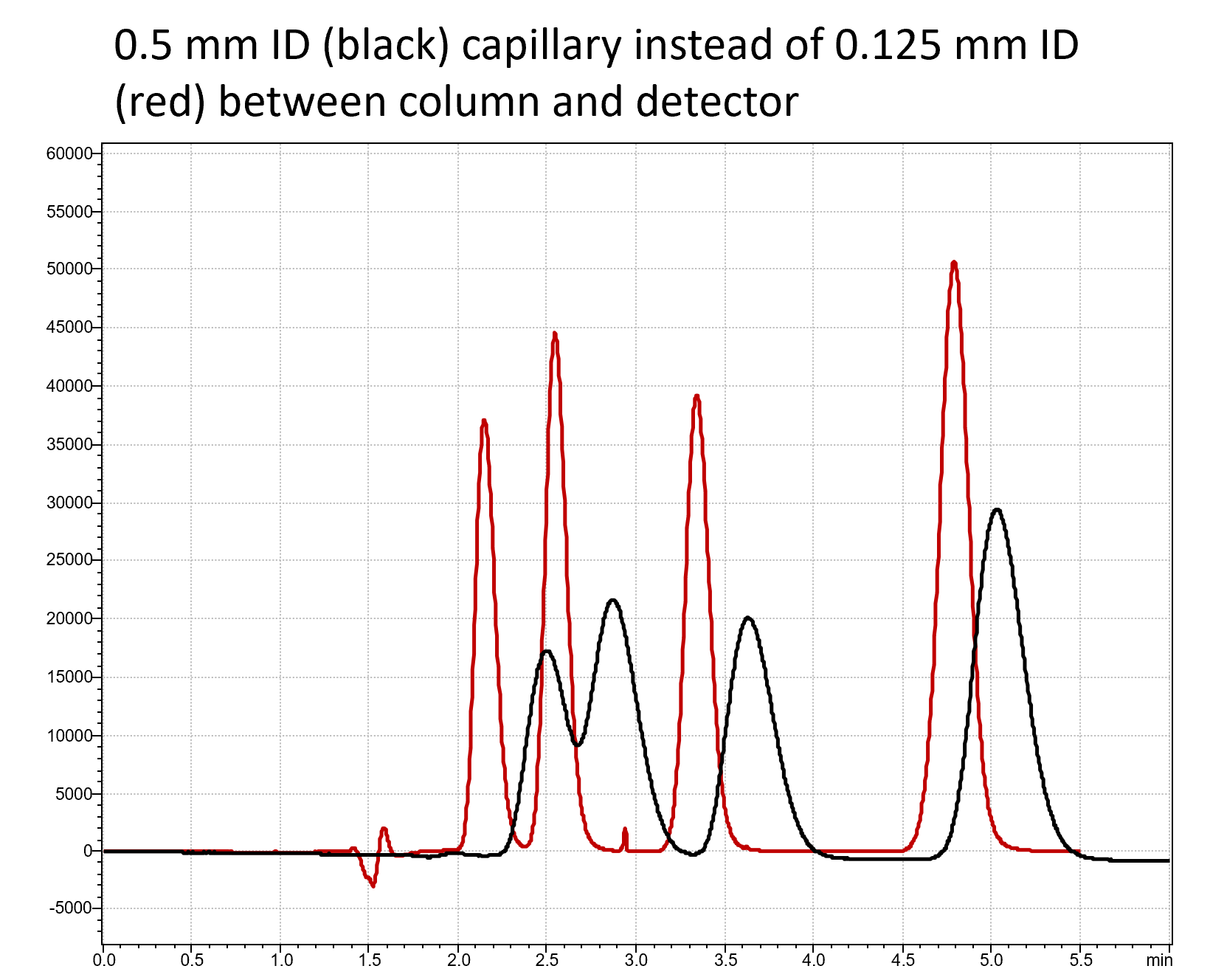

Look what happens in the chromatograph below when a wider, 0.5 mm ID capillary is used instead of a 0.125 mm ID - baseline separation is lost and the peaks have broadened. However, you should also note that narrower capillaries can generate higher back pressures in the system. Therefore, adjust the dimensions of the capillaries to your chromatographic system so that you do not reach the limits of the permissible pressure maxima.

If the dead volume of the system is increased, peak broadening is a common occurance which affects earlier retention times more than later ones. Check all connections to ensure no additional dead volumes have been introduced, such as between the column head and capillary. This is particularly important to check after a column has been changed.

In isocratic measurements, peak broadening occurs naturally due to longitudinal diffusion within the column and is therefore unavoidable. This mainly affects later eluting peaks. Switching to a gradient method can help mitigate this issue.

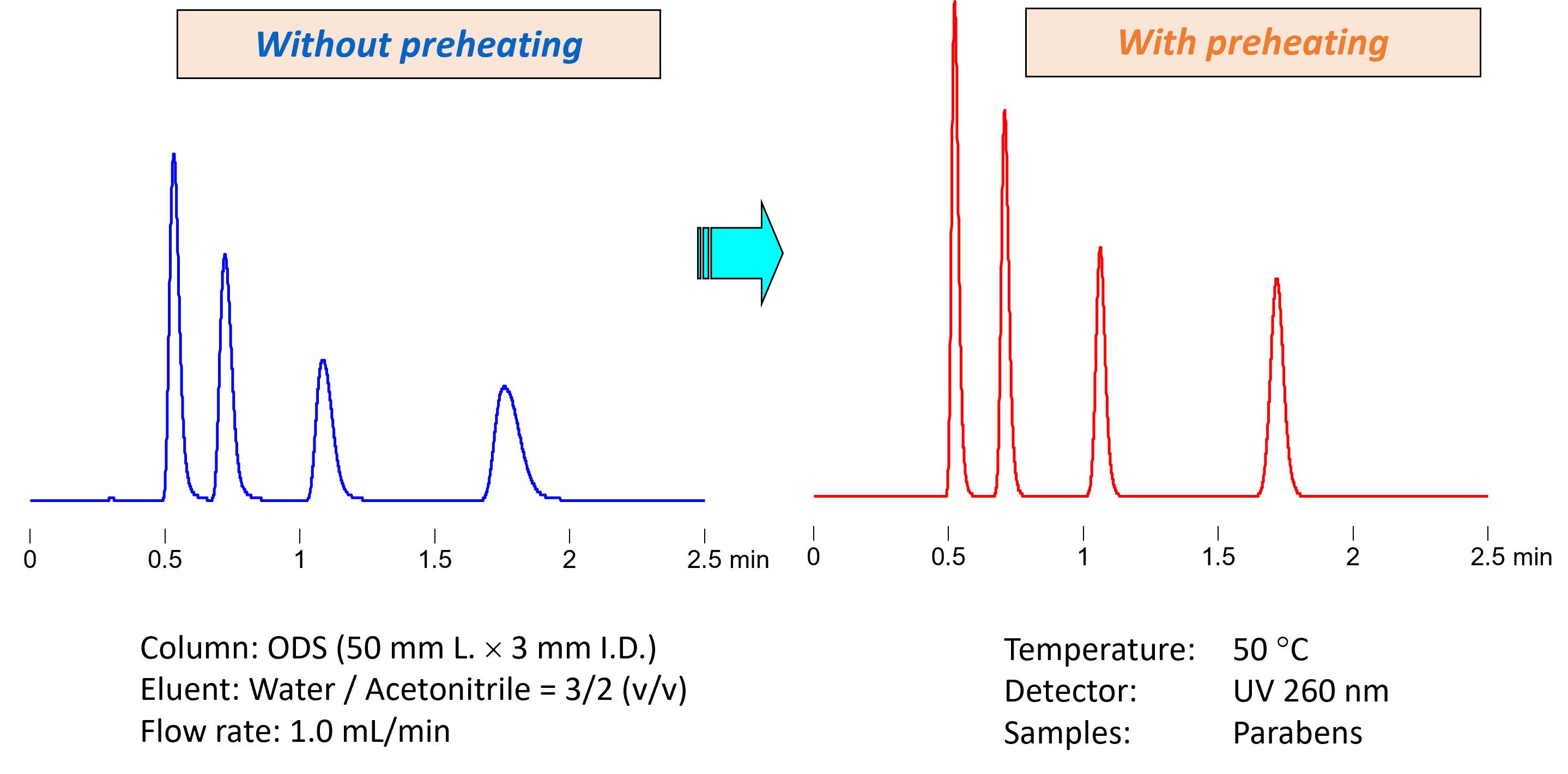

Temperature also plays a significant role in peak broadening. Temperature gradients within the column should be avoided as they promote broadening. To minimise this, always use a column oven, and ensure that the mobile phase is preheated (where possible). Without preheating, even a temperature-controlled column can experience internal temperature gradients, leading to peak broadening, as shown in the image below.

Column:

System:

As discussed in previous sections, the causes of peak broadening are diverse and cannot be resolved with a single solution. A systematic approach and comparison with a reference system are recommended. If peak broadening occurs gradually, the column is often the cause of the issue. If peak broadening suddenly changes, it's likely that the hardware or chromatographic conditions are the cause.

In the next unit we will deal with signals that should not be there – the ghost peaks.

Your Shimadzu LC Team

Intelligent Peak Deconvolution Analysis (i-PDeA II)