Ghost Peaks

HPLC Troubleshooting Course

6 - Changes in Peak Shape - Part 2

7 - Ghost Peaks

8 - Peak Area Fluctuations

9 - Retention Time Fluctuations - Part 1

10 - Retention Time Fluctuations - Part 2

11 - Column Lifespan - Part 1

12 - Column Lifespan - Part 2

13 - Detector Issues

14 - Flow Line Leakage

15 - Course Summary

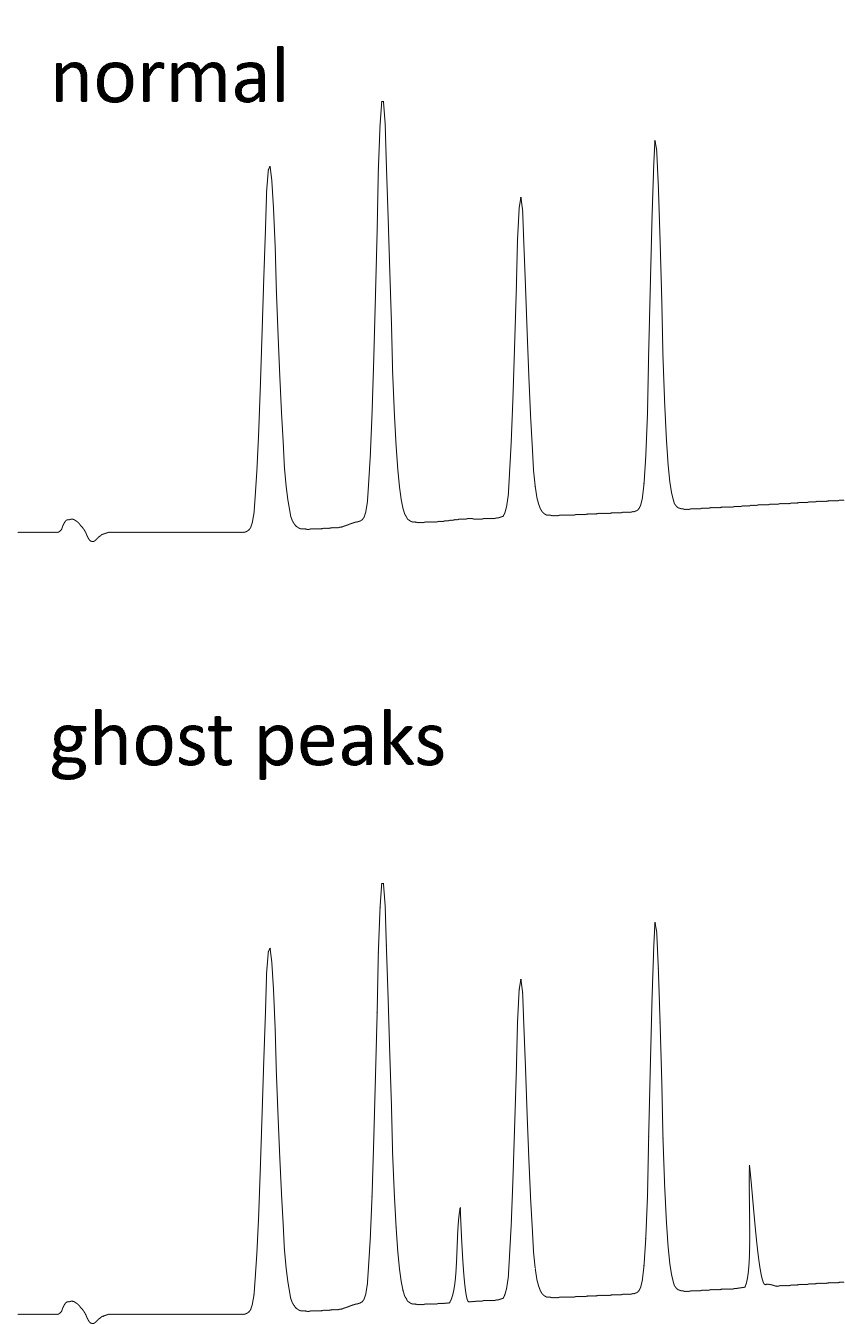

Unwanted peaks in chromatograms, often referred to as ghost peaks, can significantly interfere with data evaluation and potentially produce false results, especially if they coelute with target analytes. Consequently, avoiding these statistically occurring peaks and those arising from contaminants is a critical aspect of chromatographic analysis.

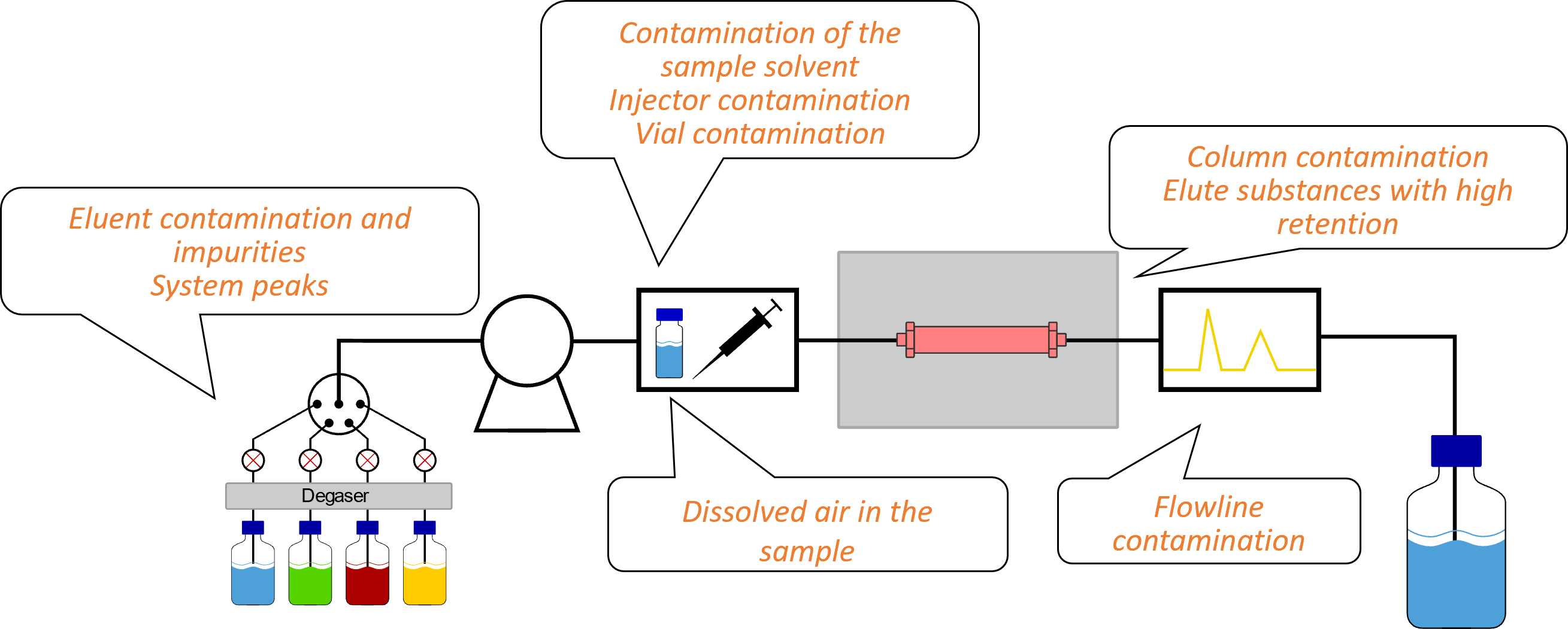

Ghost peaks can originate from various sources, including eluents, the sample or its matrix, and system-related disturbances. Below are the most common causes and ways to mitigate them:

1. Contaminated eluents

Eluents are particularly prone to contamination, which can lead to ghost peaks. To minimise this risk, replace storage containers regularly instead of continuously refilling them, as refilling can concentrate contaminants and increase disturbances.

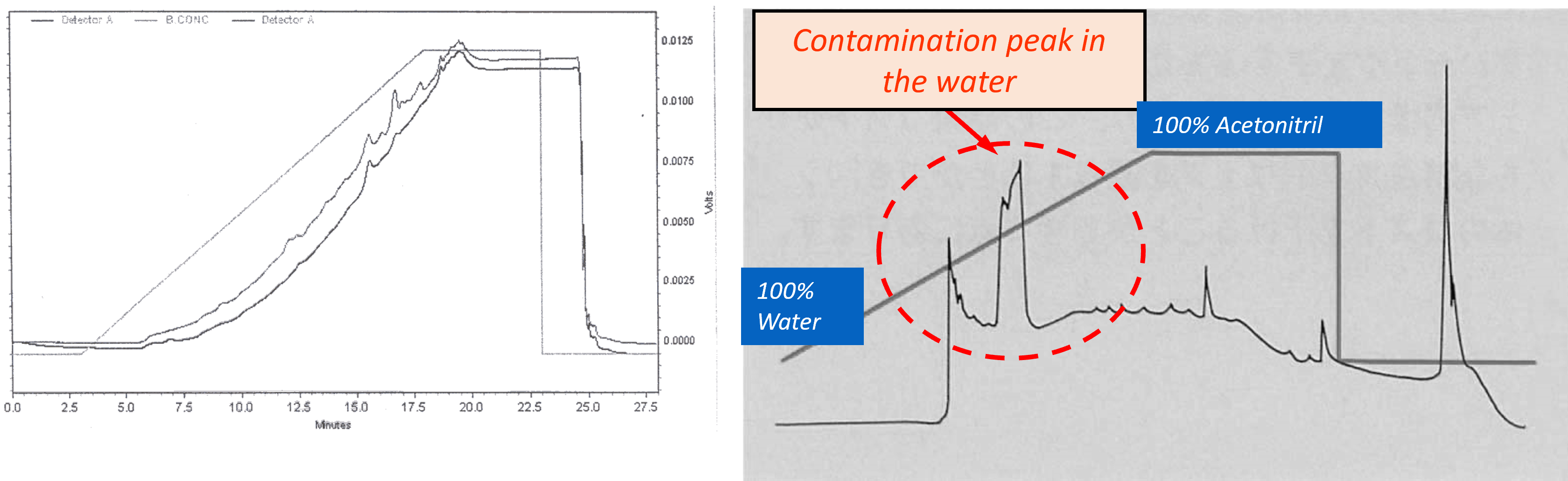

Pay special attention to water quality. If you use a water purification system, ensure it undergoes regular maintenance. The influence of contaminated water on chromatography can be seen in the following images.

For example, in a gradient run from 100% water to 100% acetonitrile, contaminants may accumulate at the column head during the early stages. As the proportion of acetonitrile increases, the elution strength grows, causing the contaminants to elute and appear as ghost peaks.

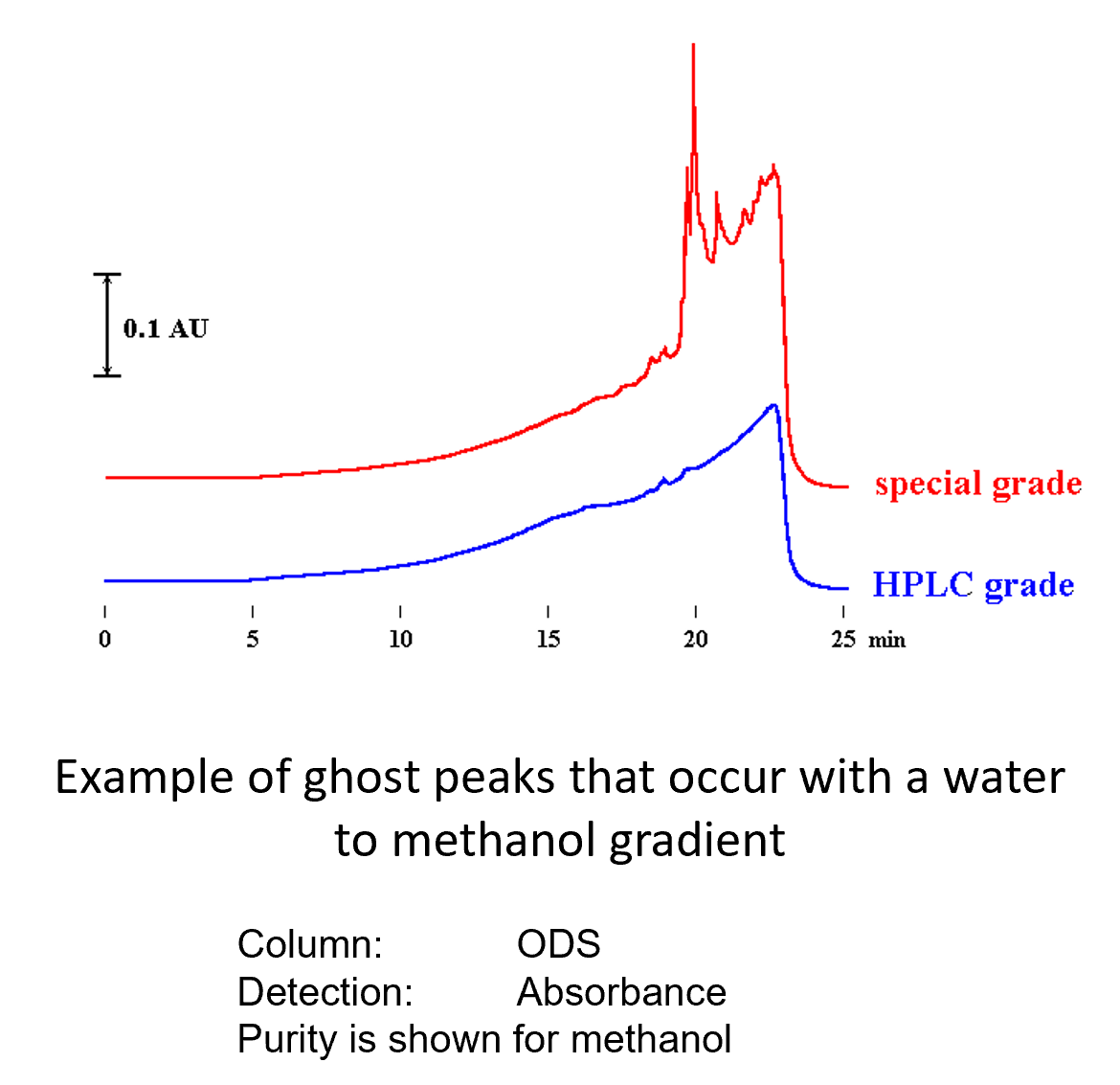

2. Incorrect solvents

Using inappropriate solvents can also result in ghost peaks. Depending on the manufacturer, certain solvents, including some marked as Special LC-MS Grade, might contain UV-active substances that interfere with UV detection but not ionisation during MS analysis. To prevent this, select solvents appropriate for your detection method and, should ghost peaks appear in blank measurements, test alternative solvent batches or switch manufacturers.

Using inappropriate solvents can also result in ghost peaks. Depending on the manufacturer, certain solvents, including some marked as Special LC-MS Grade, might contain UV-active substances that interfere with UV detection but not ionisation during MS analysis. To prevent this, select solvents appropriate for your detection method and, should ghost peaks appear in blank measurements, test alternative solvent batches or switch manufacturers.

3. Inadequate equilibration time

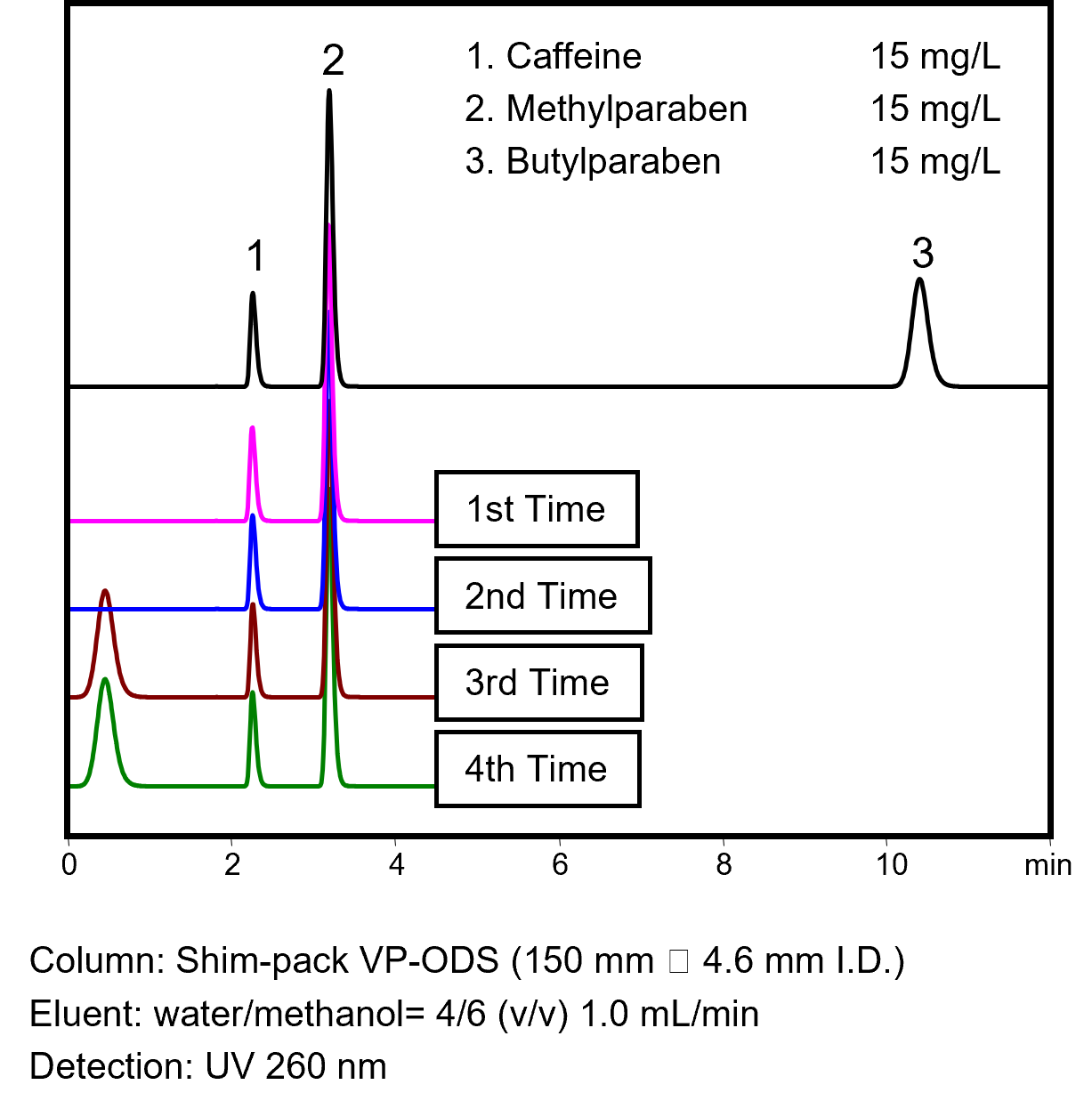

Proper method development requires sufficient runtime to elute all substances from the column. Insufficient equilibration can result in ghost peaks from carryover between measurements. This issue is particularly prevalent in samples with complex matrices. To address this, implement a rinsing step at the end of each method and ensure adequate column equilibration before starting the next run.

Proper method development requires sufficient runtime to elute all substances from the column. Insufficient equilibration can result in ghost peaks from carryover between measurements. This issue is particularly prevalent in samples with complex matrices. To address this, implement a rinsing step at the end of each method and ensure adequate column equilibration before starting the next run.

In addition to the previously mentioned factors, a contaminated sample solvent can also cause ghost peaks. Excess dissolved air in the sample may result in peaks appearing at the start of the chromatogram. Furthermore, impurities within the flow lines can elute as the mobile phase's elution strength increases, contributing to the occurrence of ghost peaks.

Things to consider daily:

- Ensure high-quality eluents and avoid contamination

- Always use the solvent suitable for the respective type of detection

- Contaminated sample solvent can also lead to ghost peaks - verify that sample preparation minimises impurities

- Regularly replace storage containers, do not refill them

- Regularly rinse the column and flow lines to remove residual contaminants

In the next course unit, we will deal with peak area fluctuations.

Your Shimadzu LC team