Retention Time Fluctuations - Part 1

HPLC Troubleshooting Course

6 - Changes in Peak Shape - Part 2

9 - Retention Time Fluctuations - Part 1

10 - Retention Time Fluctuations - Part 2

11 - Column Lifespan - Part 1

12 - Column Lifespan - Part 2

13 - Detector Issues

14 - Flow Line Leakage

15 - Course Summary

Retention time is crucial for accurate HPLC analysis, as it is used to identify analytes. The most widely used detection methods in HPLC include UV/VIS absorption, fluorescence, and refractive index detection. Optical methods like UV/VIS absorption and fluorescence are often substance-specific, ideal for compounds with chromophores or fluorophores, while refractive index detection is more general and non-selective. Fluctuations in retention time can lead to unreliable or inaccurate results, making it essential to maintain its reproducibility for consistent and accurate measurements.

This and the upcoming course units will explore the various factors that influence retention time fluctuations.

1. Influence of Temperature on Retention Time

Temperature plays a significant role in HPLC, as it directly impacts retention time. As temperature increases, the viscosity of the mobile phase decreases, leading to a reduction in back pressure. Typically, a 1°C change in temperature results in a 1–2% shift in retention time. This effect is more pronounced for late-eluting analytes, as they are more sensitive to temperature fluctuations. The following chromatogram shows four parabens measured at different temperatures.

Comparing the measurement at 20°C and 50°C, the total runtime is almost halved. This temperature effect can be leveraged to optimise or shorten methods, as long as the column's specifications are respected. However, at very high temperatures, the lifespan of most columns is expected to be reduced.

If you choose to use temperature for method optimisation, be aware that not all analytes respond the same way to temperature changes. As shown in the example on the right, while sorbic acid and benzoic acid are separated at 20°C, they co-elute at 30°C, and increasing the temperature further may even reverse their elution order. Such shifts can lead to incorrect results if not carefully monitored.

To maintain consistency and minimise temperature-related fluctuations, it's recommended to use a column oven to keep the column temperature as stable as possible.

1: Sorbic acid, 2: Benzoic acid, 3: Methylparaben

2. Influence of Flow Rate on Retention Time

In HPLC, each pump is made up of consumable parts that need to be replaced regularly to maintain performance. For example, piston seals are designed to deliver a specified volume, but as they wear, they can become leaky, affecting the flow rate. If retention times fluctuate, the issue may lie with a defective pump.

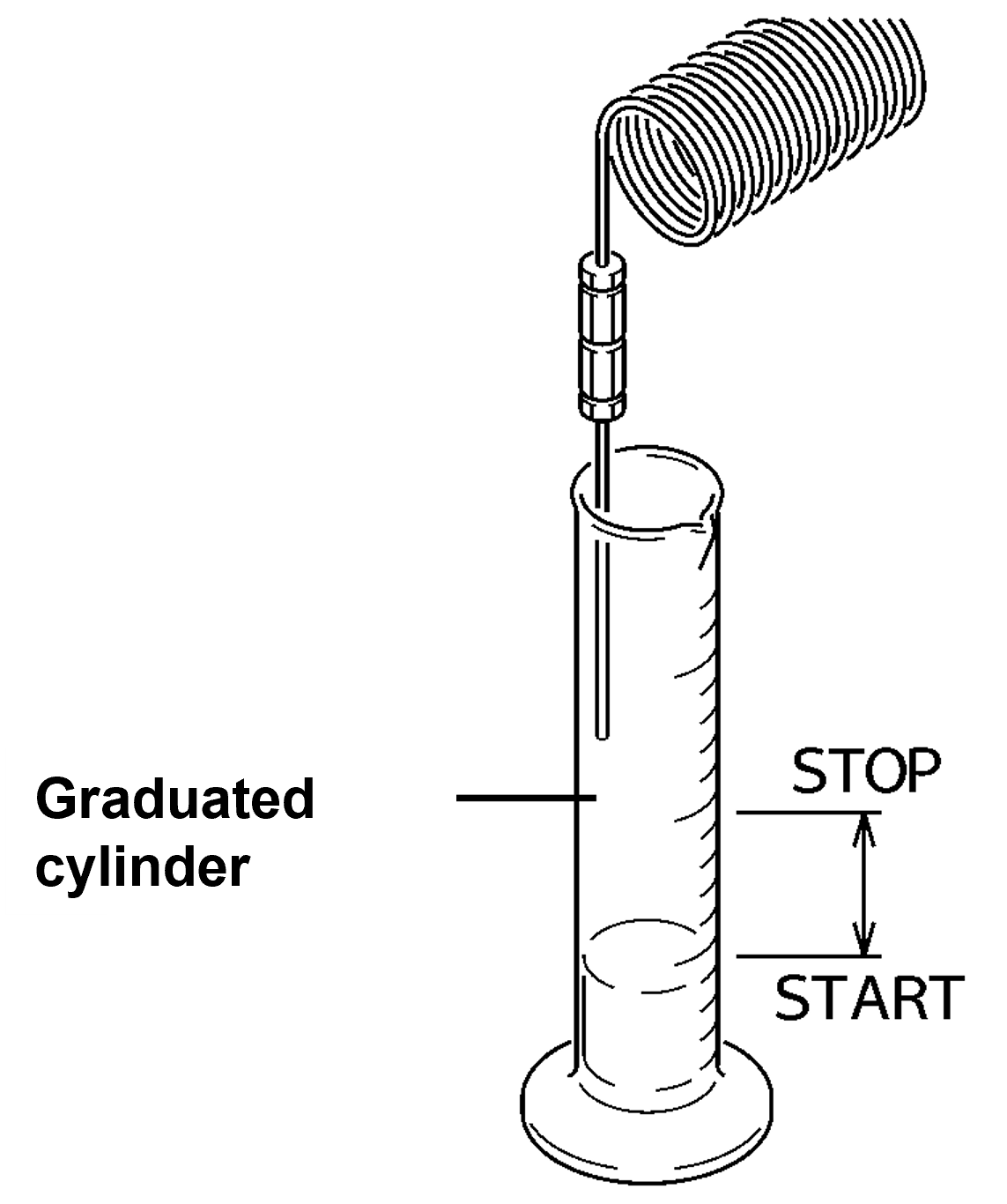

The easiest way to check pump performance is by calibrating it. Use a graduated cylinder and connect a backpressure capillary directly to the pump, setting a defined flow rate. Then, compare the time it takes to deliver a specified volume against the expected flow rate to check for discrepancies.

It’s important to regularly inspect the consumables in your HPLC system and keep spare parts on hand to quickly replace any faulty components.

Non-robust methods and inconsistent measurements can create unstable chromatographic conditions. Under such conditions, even small changes—such as fluctuations in temperature or eluent composition—can significantly impact retention time. This can result in the need to repeat samples or rework the evaluation, which can be especially problematic in regulated environments.

Investing time in developing robust methods upfront will pay off by reducing troubleshooting efforts and saving time in routine analyses.

Things to consider daily:

General:

- Perform regular system suitability tests to ensure reliable results

- Check the consumables at consistent intervals to prevent wear-related issues

- Document key parameters such as retention times and resolution for reference solutions

System:

- Utilise a column oven to maintain precise and stable temperature control

- Keep a column diary

- Keep records of system maintenance

In the upcoming course unit, we will explore further factors affecting retention time fluctuations, including the influence of eluent composition, column characteristics, and equilibration time.

Your Shimadzu LC Team