Response Variability

GC Troubleshooting Course

11 - Response Variability

12 - Retention Time Variability

13 - Course Summary & Test

Response Variability

In a well-optimised GC system, peak intensities for a standard should remain consistent from run to run. If you observe significant differences in peak heights or areas, it’s a sign that something has changed — and warrants systematic investigation.

1. First, check system suitability and maintenance records – useful clues can be found. Look for trends that would indicate whether the problem started suddenly or is a result of gradual degradation.

2. Next, consider whether the issue is related to the sample preparation:

- Check the sample concentration – an obvious point, but it can happen!

- Check that you’re following the sample prep procedure correctly.

- Check that your sample is being stored correctly and at the right temperature, as decomposition or evaporation can give rise to response problems.

- If you’re using a standard, check that it’s within its use-by date.

Ensuring your samples are properly sealed and stored (usually in the fridge) is important to extend their shelf life and avoid wasted time troubleshooting peak response issues.

3. If your sample all looks good, then the next thing to examine (and perhaps the most likely one overall) is the sample introduction:

- Has there been a change in the sample introduction method? If so, trying changing back to the original technique.

- Verify that you’re using the correct split ratio.

- Check that you’re using the correct splitless hold time (too long can lead to sample degradation or loss; too short causes incomplete sample transfer to the column).

- Check that the syringe is working correctly, the plunger moves smoothly and with no air bubbles are present.

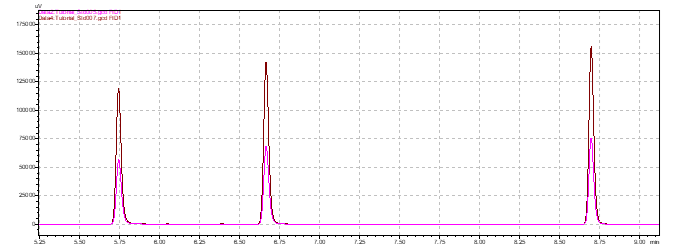

- Confirm that the autosampler is operating correctly (they rarely malfunction, but it’s worth checking). Chromatogram showing difference in samples using split ratios – e.g. 10:1 split vs 20:1 split would give approximately half the peak size for all compounds:

An unnoticed change in a sample introduction protocol – such as a different split ratio – is one possible cause of a sudden change in peak response.

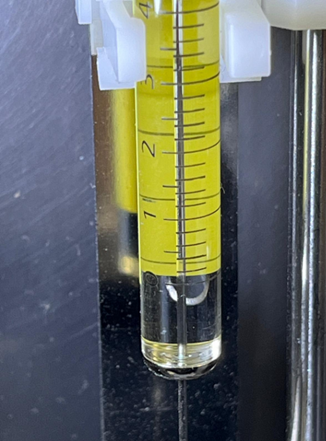

Air bubbles in a syringe

An unexpected source of a change in peak response can be air bubbles in your syringe, which could be a result of a partial blockage.

4. Finally, if no issues have been uncovered so far, then you might have one of the following:

- Could you be suffering from a dirty liner or column? If you suspect this, then clean or replace the relevant parts.

- Then check that you’ve not got fluctuating/incorrect flow rates and GC temperatures.

- Consider whether you could have a dirty or damaged detector. If so, then perform detector maintenance or replace parts. For a GCMS, clean the ion source, check and replace the filaments if required and if that does not an improvement, replace the electron multiplier.

Related Resources