Retention Time Variability

GC Troubleshooting Course

Retention Time Variability

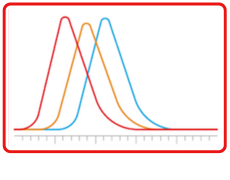

Consistent retention times are critical for reliable identification and quantification of target analytes.

While modern software algorithms can compensate for small day-to-day variations, significant or progressive shifts in retention time must be investigated and resolved promptly.

Common Causes and Troubleshooting Approach

1. Method Parameters

Sudden or unexpected changes in retention time often result from altered method conditions. Always verify that the method parameters match the standard operating procedure (SOP) or archived method files.

Key parameters to check and optimise:

- Column temperature and oven temperature program: Ensure the oven ramp and hold times are appropriate and reproducible.

- Carrier gas flow or linear velocity: Changes in flow affect analyte elution times directly. Verify and adjust flow settings based on column specifications.

- Oven equilibration time: Insufficient equilibration before injection can lead to inconsistent oven start temperatures which will cause variability in retention times, especially for more volatile compounds.

2. Inlet and Injection Issues

After confirming the method is correct, examine the inlet system, as it is a common source of RT variability.

- Leaks in inlet or column connections: Use leak detectors or pressure decay tests. Replace septa, o-rings, or ferrules as needed.

- Active sites and contamination: Dirty inlet liners or degraded column surfaces can adsorb analytes, affecting retention. Regularly maintain and replace liners, and use well-deactivated columns.

- Sample overloading: Injecting too much sample can broaden peaks and shift retention times. Dilute the sample or adjust the split ratio accordingly.

- Inconsistent carrier gas flow: Flow controllers or regulators may degrade over time. Monitor flow rates and replace faulty components.

- Oven stability: Temperature fluctuations at the start of the run can cause retention time drift. Ensure proper oven stabilization before injection by extending the equilibration time.

3. Injection Technique

- Manual injection variability: Inconsistent injection speed or volume can alter retention times. If possible, switch to an autosampler.

- Use of internal standards: Including an internal standard can help correct for small retention shifts, especially when using manual injection.

Summary Tips

- Regularly compare method files to detect changes.

- Schedule routine maintenance of inlet and flow components.

- Use autosamplers and internal standards when possible.

- Document and trend retention times to spot gradual shifts.

Related Resources