Video: How Smart FlowPilot works

HPLC Troubleshooting Course

11 - Column Lifespan - Part 1

12 - Column Lifespan - Part 2

13 - Detector Issues

14 - Flow Line Leakage

15 - Course Summary

The column is a crucial component of (U)HPLC, as it is where chromatographic separation occurs. However, columns are consumable items with a limited lifespan. This is especially relevant for high-cost columns, where maximising longevity is essential. Proper handling and maintenance significantly impact both the lifespan of the column and the number of successful injections.

The first section of "Column Lifespan" focuses on general best practices for handling HPLC columns, including strategies to prevent blockages from particles and crystallisation, proactive maintenance measures, and corrective actions when issues arise.

Each analytical separation column has specific operating conditions that must be followed to ensure optimal performance. The key parameters include:

Operating outside these parameters can lead to shifts in selectivity, loss of retention time, or even permanent column damage.

Additionally, proper handling is critical to preserving column integrity. Avoid sudden pressure fluctuations, as these can cause cracks in the packing material or create dead volumes. To prevent this:

Physical damage can also shorten a column’s lifespan. Avoid dropping the column, as impact can compromise its internal structure. Always store your columns according to the manufacturer's recommendations in the appropriate solvent. Store the column tightly closed with the supplied end caps and preferably in the supplied packaging.

Small dirt particles from the system, eluent, or sample can lead to column blockage, reducing performance and lifespan. The following preventive measures can help avoid such issues.

Since column longevity depends on sample quality, proper sample preparation is essential. Particles must be removed before injection. Syringe filters offer a simple and cost-effective solution, but if filtering is unsuitable for your samples, consider alternative techniques such as centrifugation or solid-phase extraction (SPE).

Similarly, the eluent should be free of particles to prevent blockages in both the column and system. Organic impurities in water can also cause unexpected ghost peaks in chromatograms. This issue was previously covered in Part 7 of this troubleshooting course.

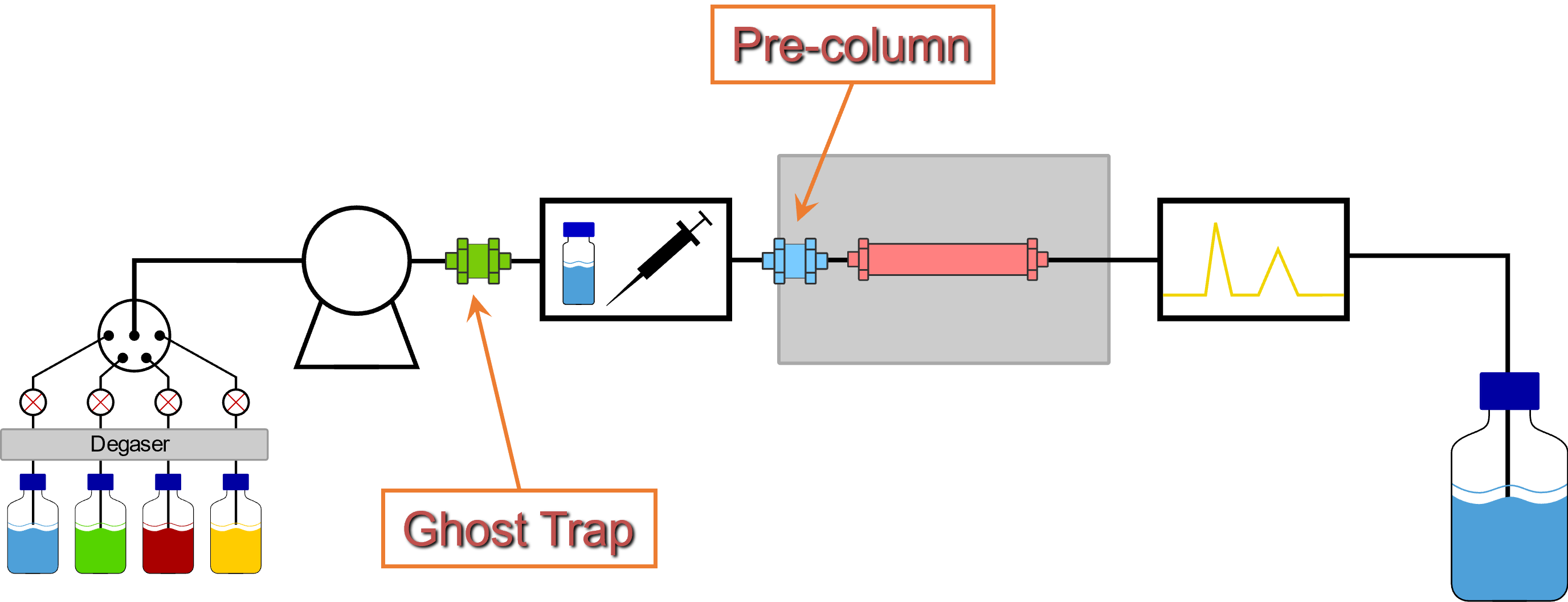

Precolumns (guard columns) are placed before the main analytical column to trap impurities and extend column lifespan. These are typically filled with the same packing material as the main column and are no more than one-tenth its size. Precolumns are easily replaceable and far more cost-effective than replacing an analytical column. If using a precolumn, always account for its minor impact on chromatographic separation during method development.

Additionally, ghost traps can be installed between the pump and injector to remove mobile phase impurities, further protecting the system.

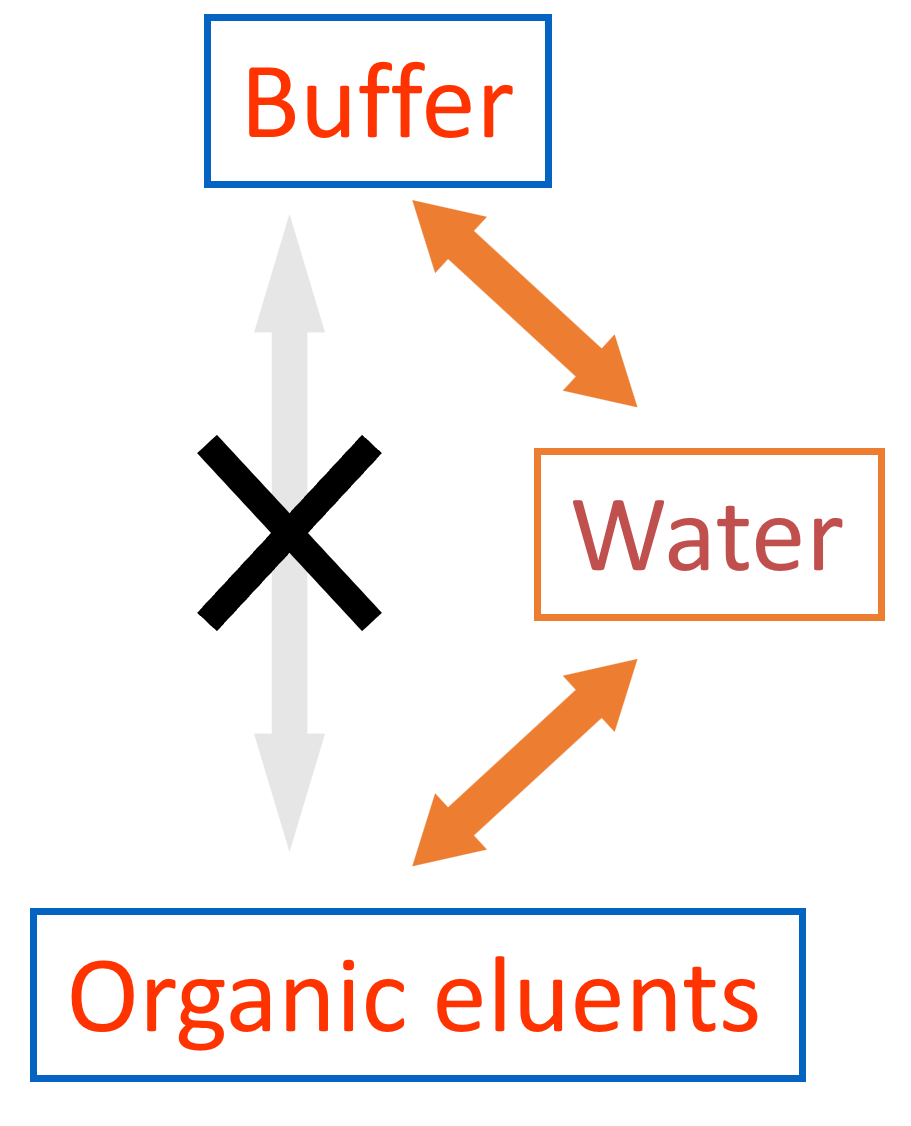

When switching eluents, always consider their miscibility to avoid precipitation. Buffers should never be replaced directly with organic solvents, as this can lead to precipitation of buffer salts. Instead, always flush the system with water between buffer and solvent changes.

Moreover, avoid leaving an eluent mixture containing an aqueous salt solution in the system after analysis, as prolonged exposure can lead to crystallisation and potential system blockages.

In the next part, we will discuss further factors that can contribute to the longevity of the column.

Your Shimadzu LC Team

Video: How Smart FlowPilot works