Search Shimadzu's range of HPLC columns to find the right one for your application.

Retention Time Fluctuations (Part 2)

LCMS Troubleshooting Course

11 - Retention Time Fluctuations - Part 2

12 - Changes in Chromatographic Resolution

13 - Changes in MS Response

14 - Undesired Fragmentation & Ion Source Settings

15 - Course Summary & Quiz

Part 2: Stationary Phase, Instrument Related Issues and Best Practices

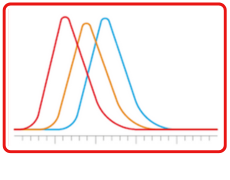

Retention time is a critical parameter in LC and LCMS, used to identify analytes reliably. They are characteristic of the analyte under certain chromatographic conditions with a specific column, which allows for confidence in analyte identification. Fluctuations can compromise data accuracy, reproducibility, and confidence in analytical results.

This topic is divided into two parts:

- 1. Temperature effects, eluent composition, and flow rate issues.

- 2. Stationary phase, instrument related issues, and best practices.

This week we are focusing on the issues related to the instrument and stationary phase.

1. Column & Stationary Phase Factors

| Cause | Solutions |

|---|---|

| Stationary Phase Changes |

Avoid memory effects by not using columns used with ion pairing reagents for non-ion-pair methods

Recondition or replace columns that are dried out or contaminated.

|

| Column Equilibration |

Allow full equilibration between methods or after storage solvent washout

|

| Column Dimensions |

Confirm correct column length, ID and particle size for the method

|

2. Instrument Related Issues

| Cause | Solutions |

|---|---|

| Air Bubble in Pump |

Purge thoroughly, especially when switching solvents

This is often associated with changes in pressure.

|

| Needle Rinse Solvent |

Prevent strong needle rinse solvent from reaching the column during injections

|

| Check Valve Issues |

Purge with isopropanol to restore check valve function.

Replace the check valve if the issue persists.

This problem is often observed with pressure trace issues, where the ripple is greater than 2 bar and can look like a saw tooth.

|

| Sample Diluent Mismatch |

Ensure the diluent matches mobile phase to prevent retention shifts

|

| Wrong Cycle Time |

If the cycle (or loop) time is not correctly set, the number of data points collected across the peak might be insufficient which can cause the apex of the peak to shift, giving a change in retention time. This is often associated with changes in peak area, and poorly defined peak shape as the majority of the peak is not correctly identified.

|

3. Best Practices to Maintain Retention Time Stability

Never leave buffers in the system. Rinse them out with pure water (depending on the column) or maintain a low flow rate to prevent salt precipitation.

Never leave buffers in the system. Rinse them out with pure water (depending on the column) or maintain a low flow rate to prevent salt precipitation.

Perform regular system tests to monitor the health of your system and column, ensuring you have a reliable baseline for troubleshooting if issues arise.

Perform regular system tests to monitor the health of your system and column, ensuring you have a reliable baseline for troubleshooting if issues arise.

Control system temperature. Whether for the column, detector, or autosampler, stable temperature conditions are critical for reproducibility and performance. Temperature fluctuations can significantly impact various components.

Control system temperature. Whether for the column, detector, or autosampler, stable temperature conditions are critical for reproducibility and performance. Temperature fluctuations can significantly impact various components.

Rinse your system and column regularly to remove contaminants and extend their lifespan.

Rinse your system and column regularly to remove contaminants and extend their lifespan.

Handle your column with care. It is the heart of your system, along with the eluents. Avoid physical shocks, sudden pressure changes, and operation outside the manufacturer’s specifications.

Handle your column with care. It is the heart of your system, along with the eluents. Avoid physical shocks, sudden pressure changes, and operation outside the manufacturer’s specifications.

Standardise eluent preparation procedures to ensure consistency and reliability in your analyses.

Standardise eluent preparation procedures to ensure consistency and reliability in your analyses.

Perform regular system suitability test to check for retention time and resolution

Perform regular system suitability test to check for retention time and resolution

Document retention times and resolution

Document retention times and resolution

Inspect the system for column leaks and worn consumables

Inspect the system for column leaks and worn consumables

We have now completed this two part series for the causes and solutions for retention time fluctuation. Next week, we will be looking at changes in chromatographic resolution.

Your Shimadzu LCMS Team

Next week's units will be delivered directly to your inbox according to your weekly schedule, but if you can't wait and would prefer to continue with the course now, click here.

Related Resources

-

-

Watch short videos explaining analytical intelligence features of Shimadzu HPLC systems

-

Learn about our beginnings, dating back to 1875, through to modern day Shimadzu.